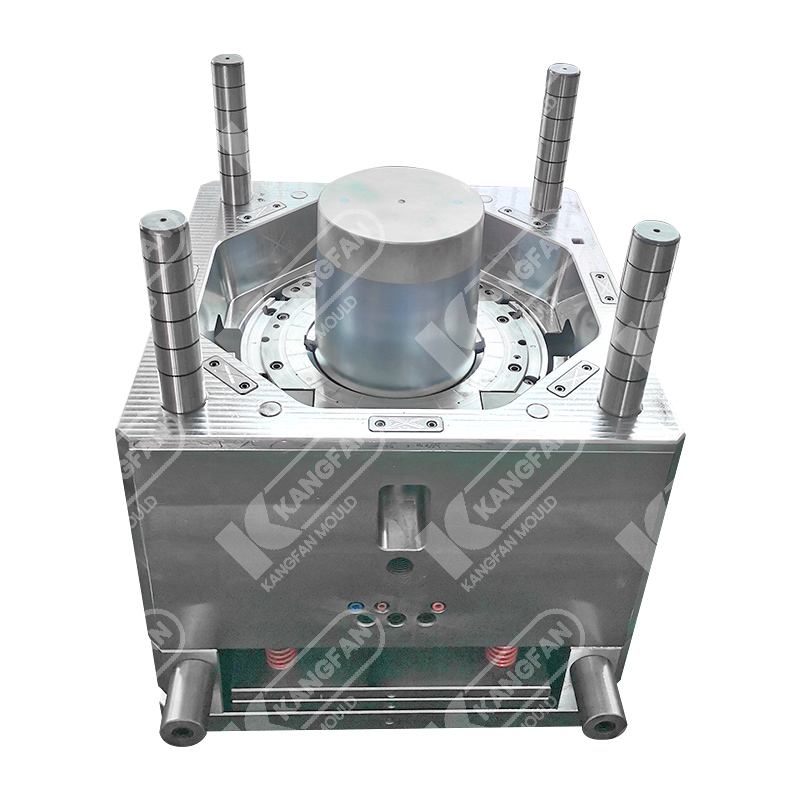

Big on Utility: Unraveling the Art of 20L Bucket Moulds for Heavy-Duty Applications

Unravelling the art of 20L bucket moulds reveals the precision and expertise required to create durable and reliable buckets for heavy-duty applications. These moulds play a vital role in producing large-capacity buckets that are extensively used in industrial, construction, and commercial settings. Here's a closer look at the key aspects involved in crafting 20L bucket moulds for heavy-duty utility:

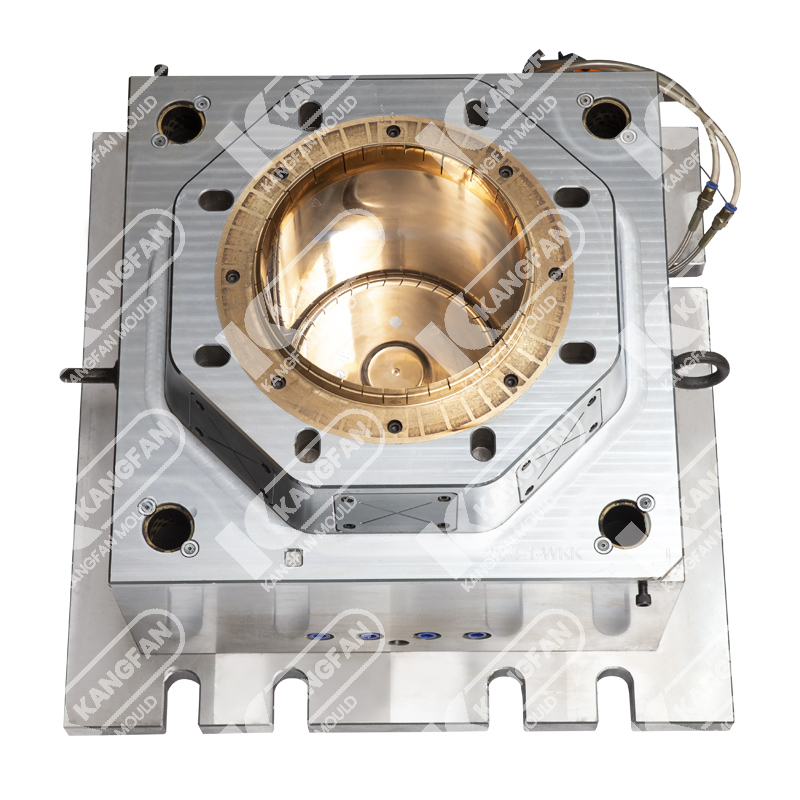

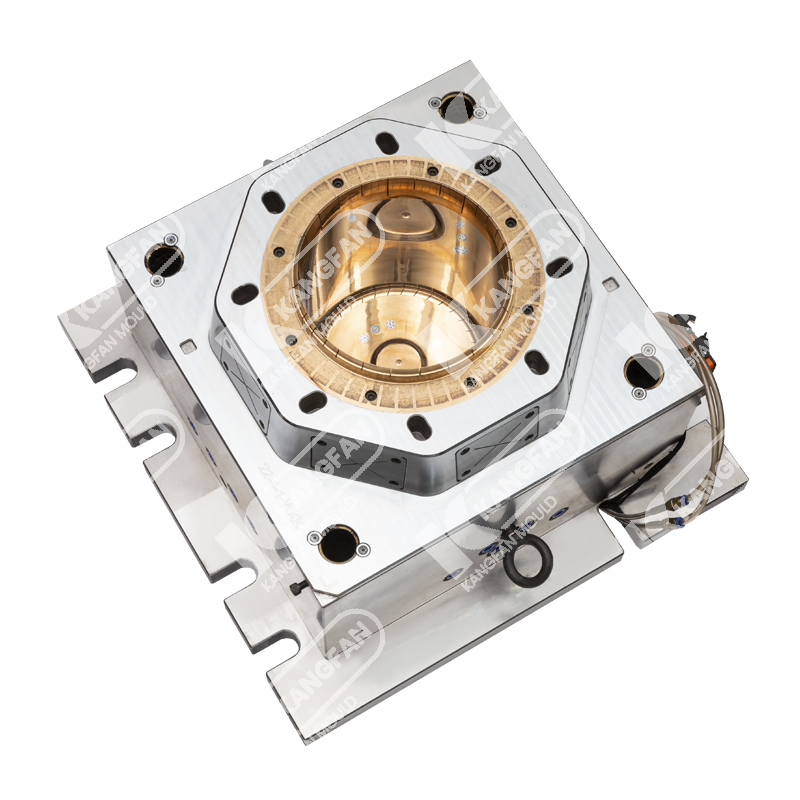

Robust Design and Engineering: Creating a 20L bucket mould requires meticulous design and engineering. Skilled designers work on detailed 3D models and prototypes to ensure that the mould can withstand the stresses of large-scale production and heavy-duty usage.

Material Selection: The choice of material for the 20L bucket mould is critical for its durability and longevity. High-quality and robust materials, such as high-grade steel, are commonly used to ensure the mould's stability and resistance to wear.

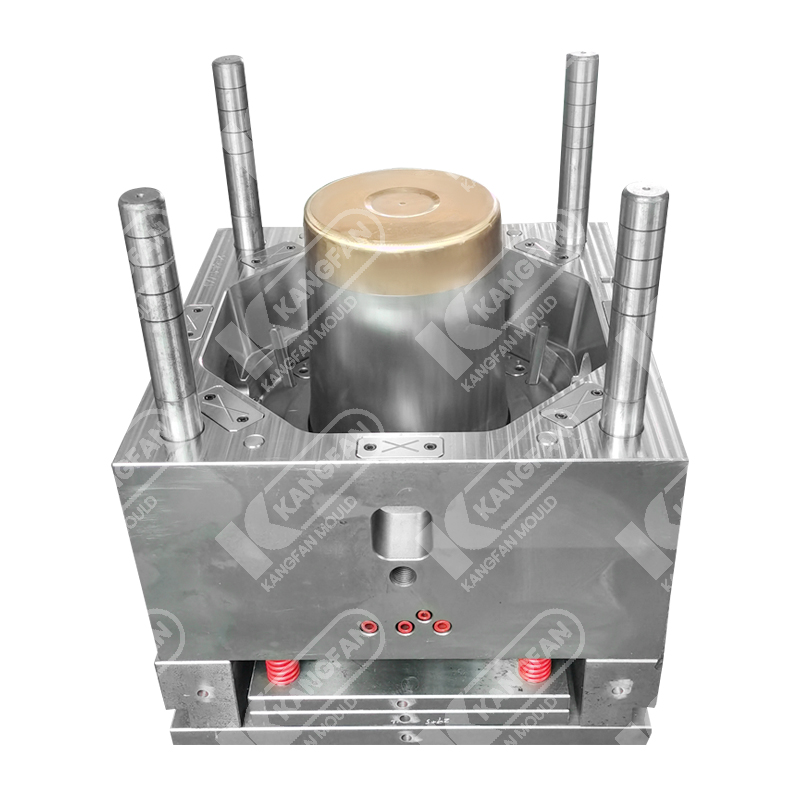

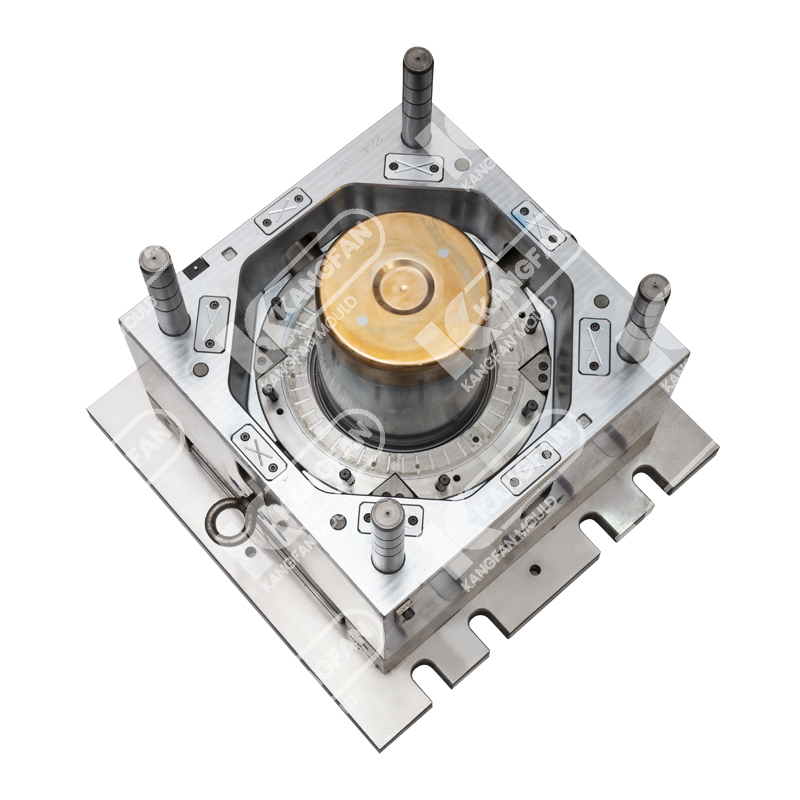

Injection Moulding Process: The 20L bucket mould is used in the injection moulding process. This process involves injecting molten plastic into the mould cavity at high pressure to form the bucket.

Wall Thickness and Strength: Designing the mould to create a consistent wall thickness for the 20L bucket is essential to ensure its structural integrity and strength. The mould should be able to produce buckets with the necessary thickness for heavy-duty applications.

Reinforcements and Stiffeners: To enhance the bucket's strength, moulds may include features for adding reinforcements or stiffeners to specific areas of the bucket, such as the base and handles.

Lid and Handle Integration: Many 20L buckets come with lids and robust handles for ease of use and transportation. The mould design includes features for the seamless integration of these components.

Cooling System: The 20L bucket mould requires an efficient cooling system to ensure proper solidification of the plastic and prevent warping or deformities during the injection process.

Ejection System: The mould is equipped with a reliable ejection system to safely release the solidified 20L bucket from the mould cavity once the injection process is complete.

Venting: Proper venting in the mould is crucial to allow air and gases to escape during the injection process, ensuring the bucket's quality and appearance.

Quality Control: The final step in crafting 20L bucket moulds is rigorous quality control. Each bucket undergoes inspection to ensure it meets specific quality standards, including dimensions, strength, and functionality.

In conclusion, the art of 20L bucket mould Maker involves precise design, engineering, and material selection to create durable and reliable buckets for heavy-duty applications. From the injection moulding process to integrating reinforcements and ensuring structural strength, every aspect of the mould design contributes to crafting 20L buckets that can withstand demanding industrial and commercial usage. These heavy-duty buckets serve as essential utility tools in various industries, contributing to efficiency, productivity, and convenience in heavy-duty applications.

中文简体

中文简体 English

English

.jpg)