Product Design-Ribs and Gussets

When designing ribs and gussets, it is important to follow the proportional thickness guidelines shown in the Example of Rib Design illustra...

News Center

-

Product Design-Undercuts

Because of the rigidity of most engineering thermoplastic resins, undercuts in a part are not recomm...

-

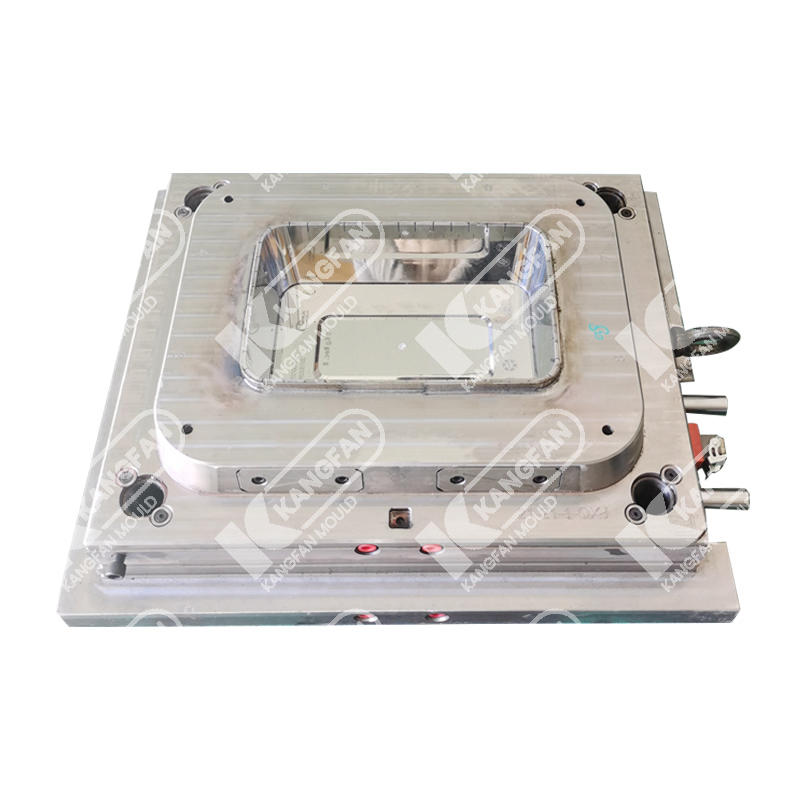

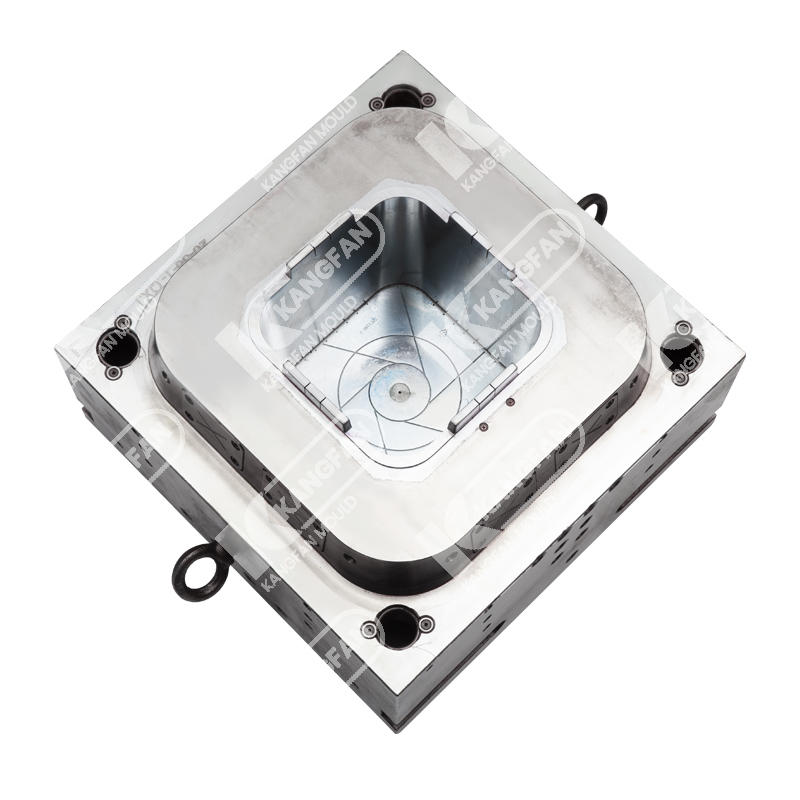

Mold Design

Mold design and construction requires special attention for optimal product quality and reliable mol...

-

Draft Angle

So that parts can be easily ejected from the mold, walls should be designed with a slight draft angl...

中文简体

中文简体 English

English