Crafting Convenience: The Ingenious World of Paint Bucket Cover Handle Molds

Painting projects, whether they are small touch-ups or large-scale renovations, often require the use of buckets to hold and transport paint. These buckets, typically made from durable materials such as plastic or metal, are essential for ensuring the smooth and efficient flow of work. But what many people may not realize is that the often-overlooked component that enhances the usability and convenience of paint buckets is the cover handle mold.

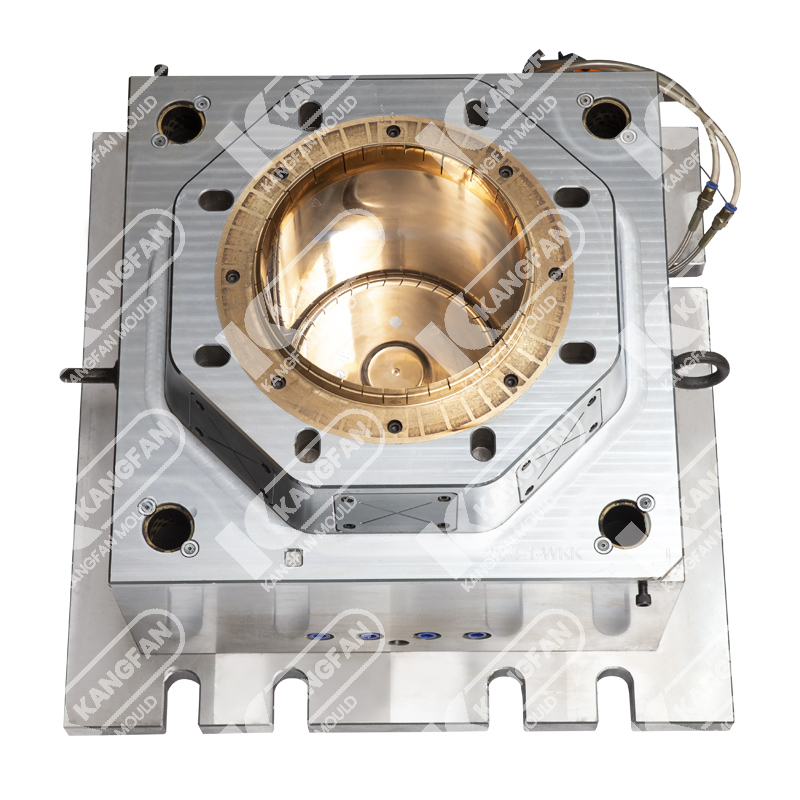

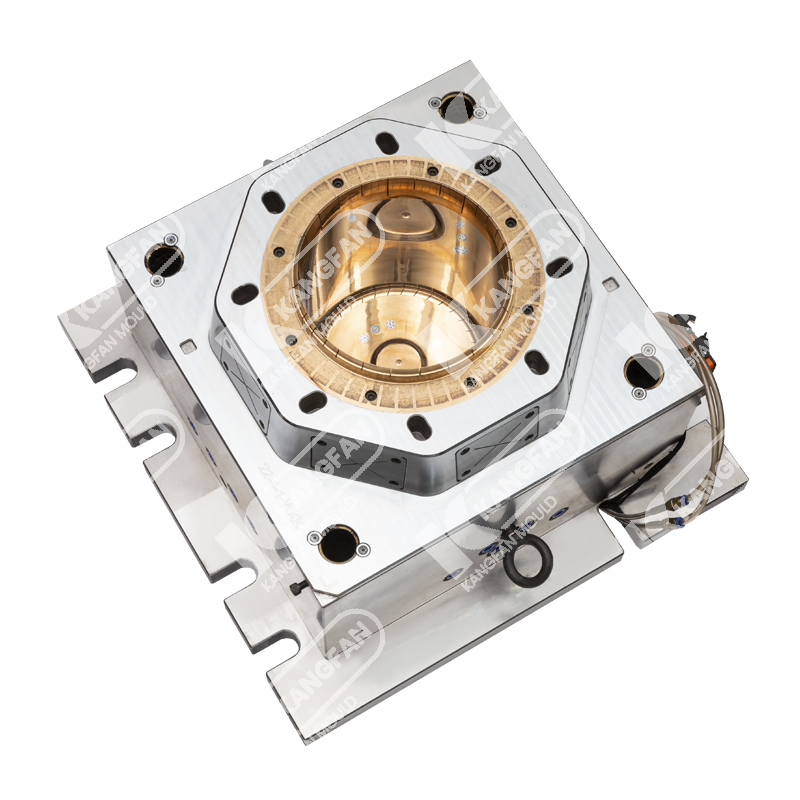

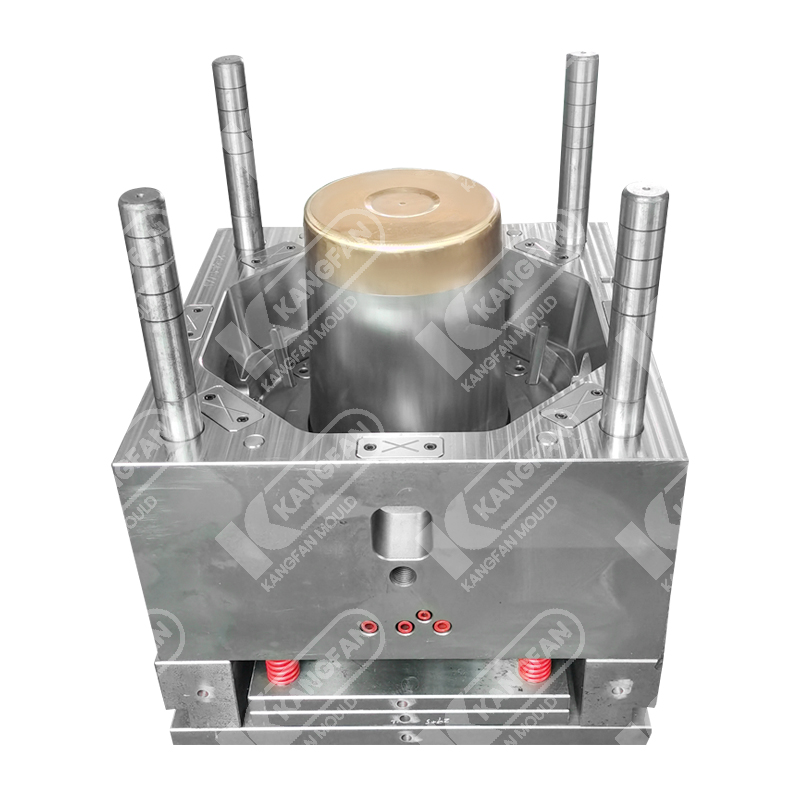

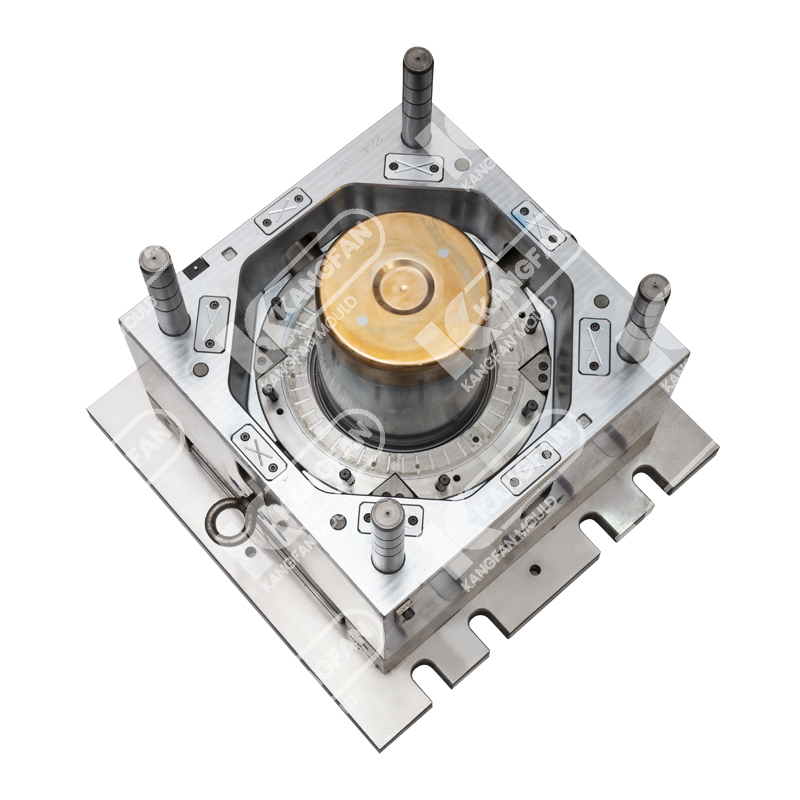

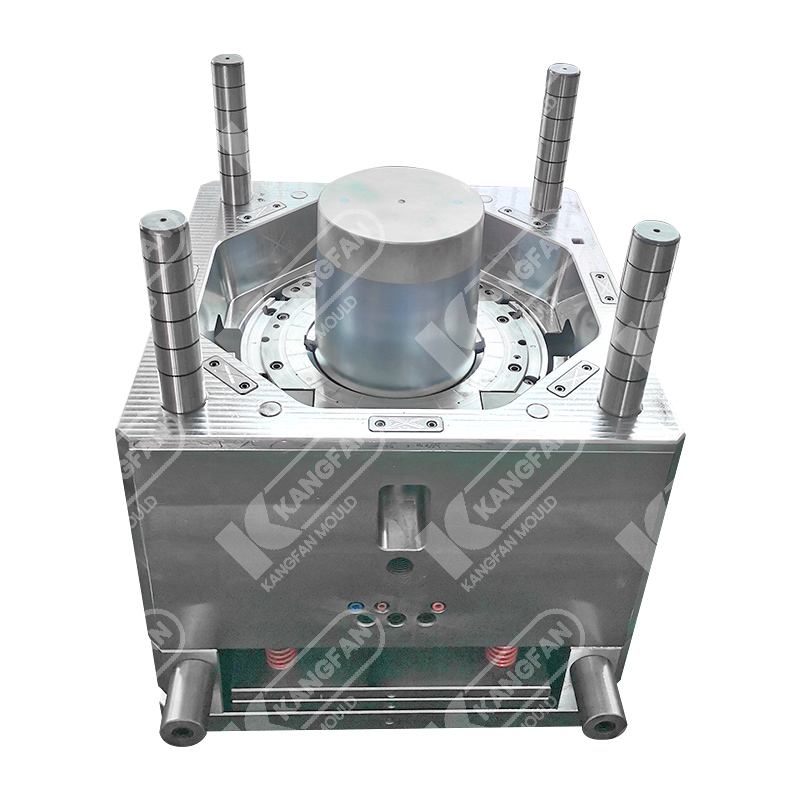

Cover handle molds are specially designed molds used in the manufacturing process of paint bucket covers. These molds play a crucial role in creating the handle that allows users to easily carry and manipulate the bucket without any hassle. They are usually made from high-quality materials such as steel or aluminum to ensure durability and longevity.

One of the key features of these molds is their ability to create handles with ergonomic designs. Ergonomics is the science of designing products that fit the needs and capabilities of the people who use them. In the case of paint bucket cover handle molds, this means creating handles that are comfortable to hold, reducing strain on the hands and wrists.

The handle molds are carefully engineered to have the right shape, size, and texture to fit the hand of the user. They can be customized based on specific requirements, such as the width and length of the handle, as well as the level of grip provided. This attention to detail ensures that painters can hold the bucket securely, even when it is full of paint, preventing accidents and spillages.

Another important feature of paint bucket cover handle molds is their ability to withstand the pressure and force applied during the manufacturing process. These molds undergo a series of intense processes, including injection molding, to create the final handle shape. They need to be strong enough to withstand the high temperatures and pressures used during plastic injection molding. This ensures that the handle is properly formed and securely attached to the paint bucket cover.

The use of cover handle molds also allows for efficient and consistent production of paint bucket covers. These molds can be designed with multiple cavities, meaning that multiple handles can be produced simultaneously, increasing productivity and reducing production time. Additionally, the molds can be easily customized or replaced, allowing manufacturers to adapt to changing customer demands or produce handles in different sizes or colors.

The versatility of paint bucket cover handle molds is not limited to their use in the paint industry. These molds can also be used to produce handles for other types of containers, such as pails or buckets used in the chemical, food, or construction industries. This demonstrates the wide range of applications for these molds and their importance in various sectors.

In conclusion, paint bucket cover handle mold manufacturers play a crucial role in enhancing the usability and convenience of paint buckets. These molds are designed with ergonomic considerations in mind, ensuring that the handles are comfortable and easy to hold. They are also built to withstand the pressure and force of the manufacturing process, ensuring durability and longevity. With the ability to produce handles efficiently and consistently, these molds contribute to the smooth production of paint bucket covers in various industries. The ingenious world of paint bucket cover handle molds is truly a testament to the importance of attention to detail and innovation in industrial manufacturing.

中文简体

中文简体 English

English

.jpg)