Custom Round Plastic Bucket Mould Revolutionizing Packaging Solutions In Various Industries

Custom Round Plastic Bucket Moulds play a pivotal role in the manufacturing industry, offering a versatile and efficient solution for packaging needs. These molds are designed with precision and tailored to meet specific requirements, providing manufacturers with the flexibility to create unique and customized plastic buckets. We will delve into the key aspects of Custom Round Plastic Bucket Moulds, including their components, product features, applications, current status, and future prospects.

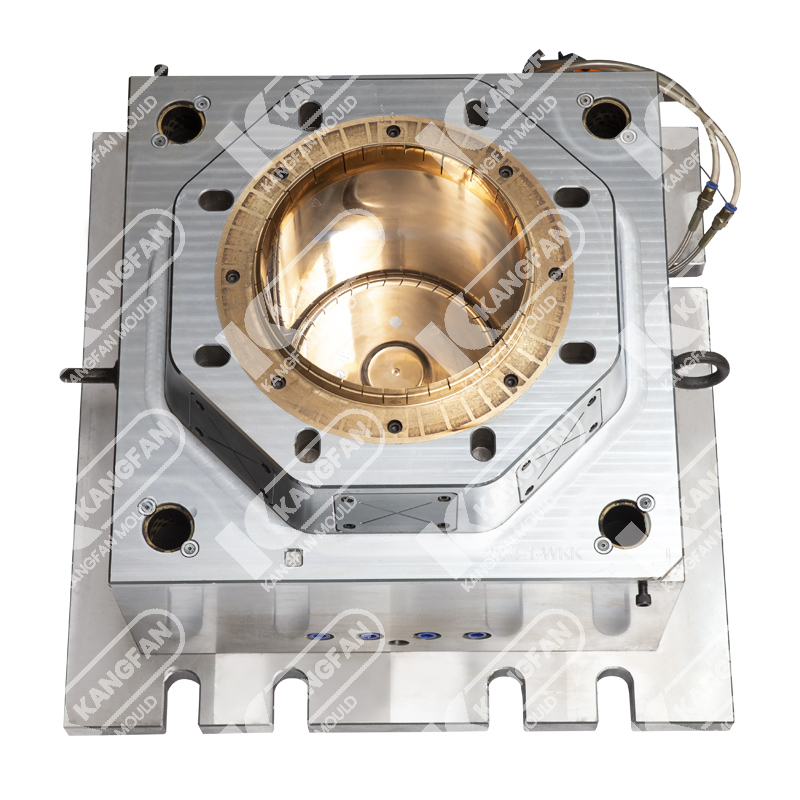

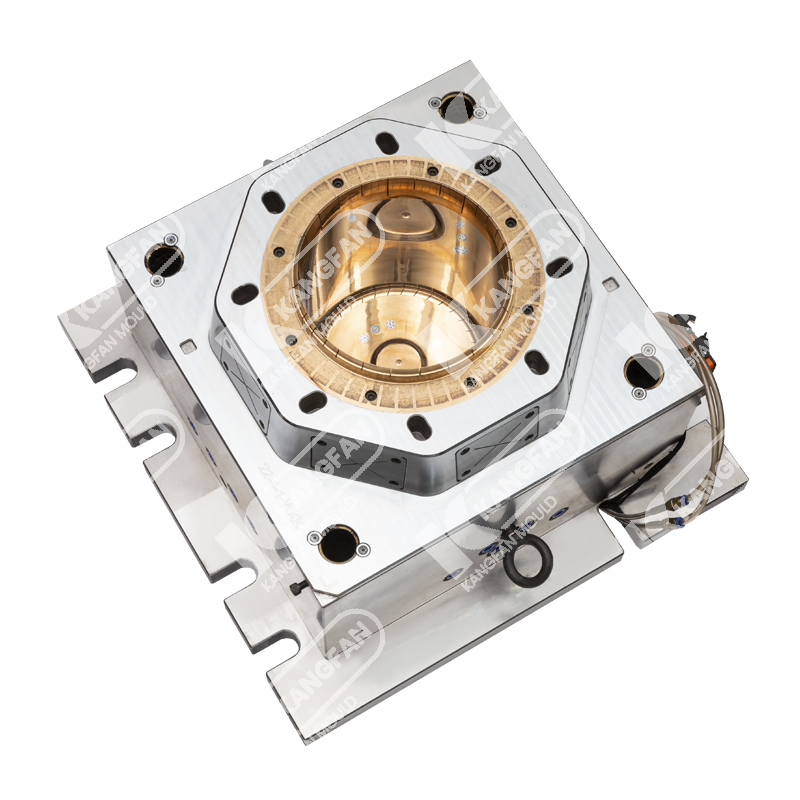

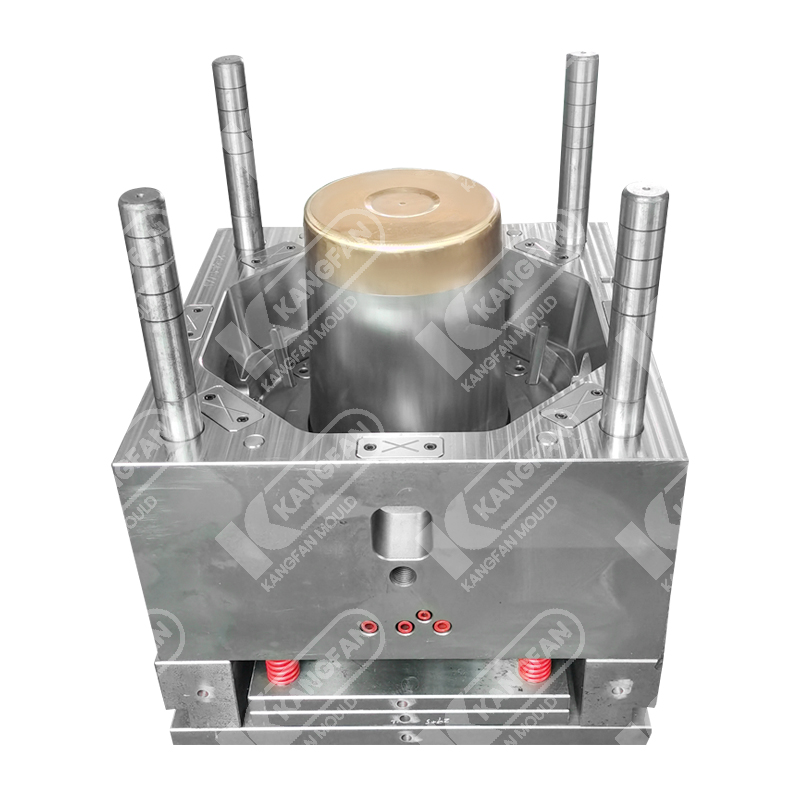

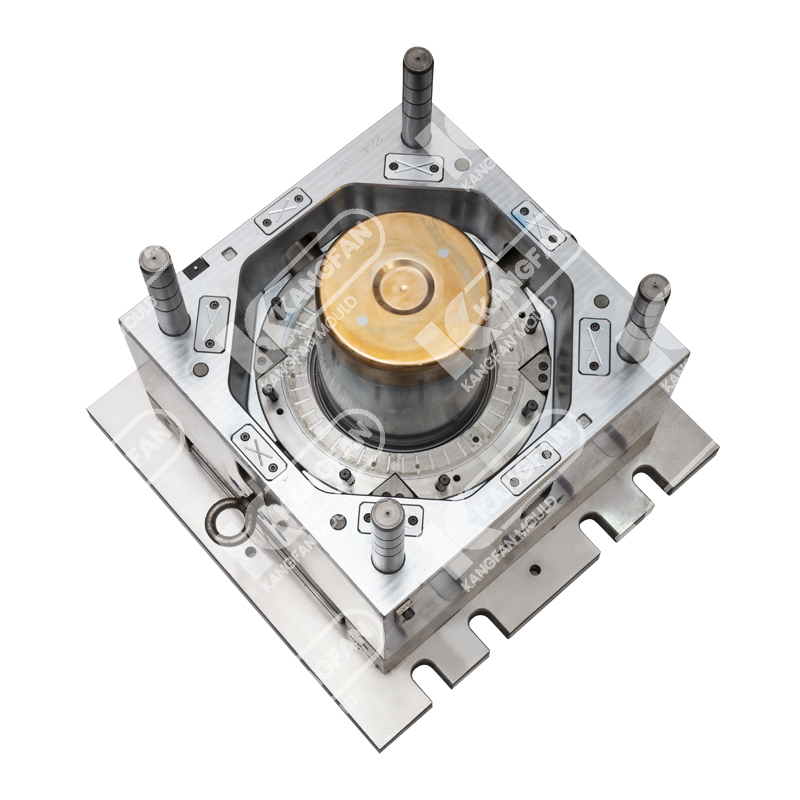

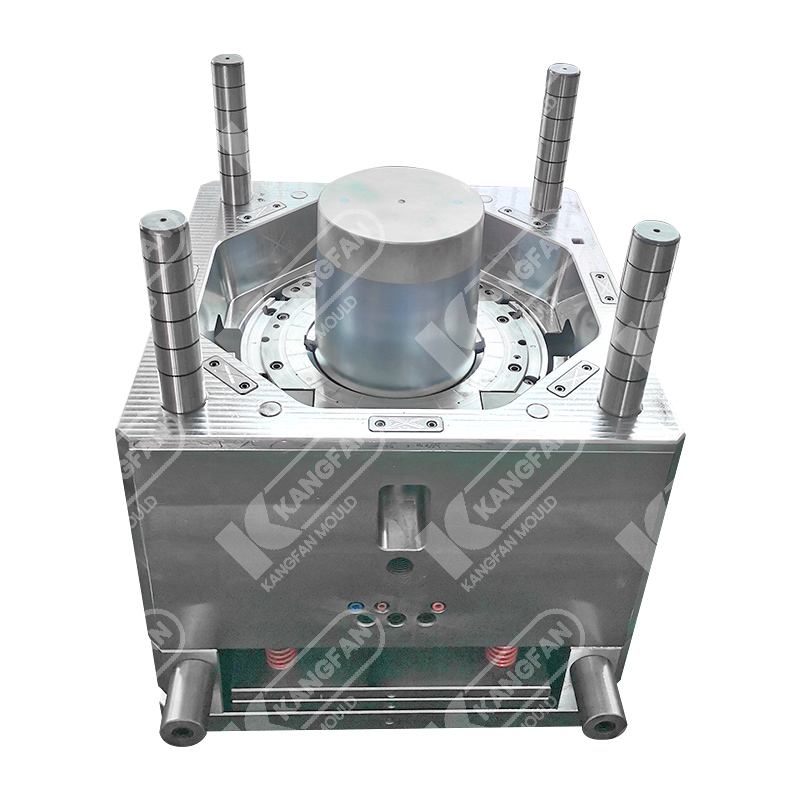

The Custom Round Plastic Bucket Mould comprises various components, including the core, cavity, runner system, and cooling system. These components work in harmony to shape molten plastic into the desired bucket form. The design intricacies are crucial to achieving consistency and quality in the final product. The moulding process involves injecting molten plastic into the cavity, allowing it to cool and solidify, and then removing the moulded bucket from the mould. This process can be repeated multiple times to produce a large number of identical buckets.

Custom Round Plastic Bucket Moulds boast several features that set them apart in the industry. Precision engineering allows for the creation of buckets with smooth surfaces, uniform thickness, and intricate details. These molds can be customized to accommodate different sizes, colors, and designs, providing manufacturers with enough flexibility. The mould ensures that the buckets have a smooth and uniform finish, with precise dimensions and accurate shape. It also allows for customization of features such as handles, lids, and specific designs or logos on the buckets.

The applications of Custom Round Plastic Bucket Moulds are vast and diverse. They are widely used in industries such as food and beverage, agriculture, chemicals, and more. These molds enable the production of buckets for storing liquids, powders, and solid materials. The customization options make them suitable for branding and promotional purposes, enhancing product visibility.

As of now, Custom Round Plastic Bucket Moulds have gained significant traction in the manufacturing sector. Their ability to produce high-quality, customized buckets efficiently has made them the right choice for many industries. Manufacturers appreciate the cost-effectiveness and quick turnaround time offered by these molds. The versatility and cost-effectiveness of plastic buckets make them a popular choice for packaging and storage purposes. As a result, there is a growing need for custom-made plastic bucket moulds to meet specific requirements of different industries.

The future of Custom Round Plastic Bucket Moulds looks promising, with ongoing advancements in mold design and manufacturing technologies. As the demand for sustainable and eco-friendly packaging solutions grows, these molds can be adapted to work with recycled materials, contributing to a greener and more environmentally friendly manufacturing process. Additionally, innovations in automation and digitalization are expected to further streamline the production of custom plastic buckets.

Custom Round Plastic Bucket Moulds represents a crucial element in the manufacturing landscape, providing a tailored and efficient solution for packaging needs. Their versatile design, coupled with a range of customizable features, makes them important in various industries. As technology continues to advance, these molds will likely play a pivotal role in shaping the future of plastic packaging, offering sustainable and innovative solutions for manufacturers worldwide.

PREV:Exploring The Dominance Of Gallons Package Bucket Moulds In The IndustryNEXT:Innovation In Rectangular Multipack Buckets And Paint Bucket Cover Handle Molds

中文简体

中文简体 English

English

.jpg)