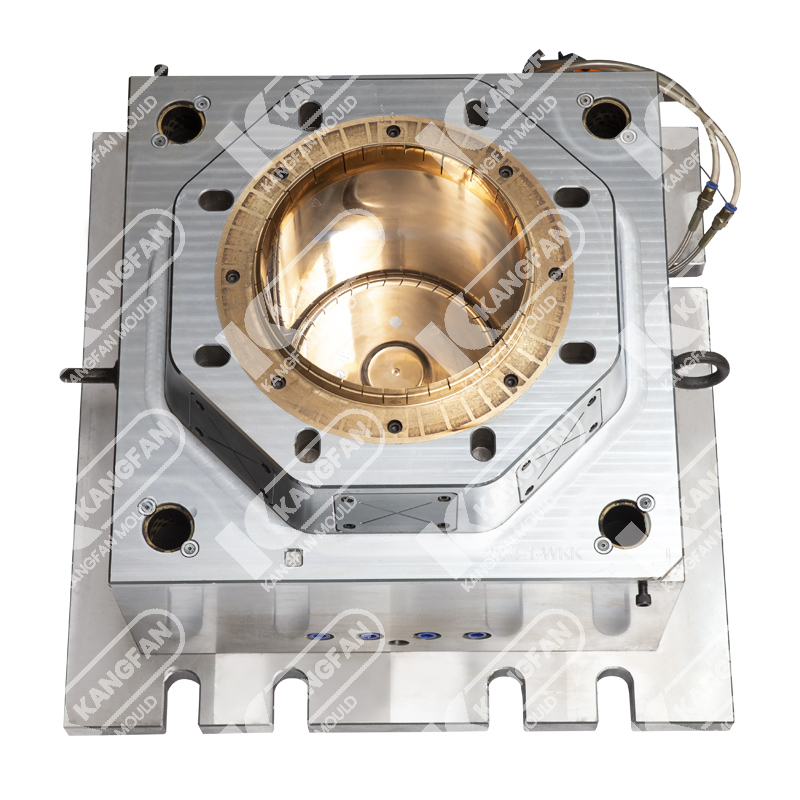

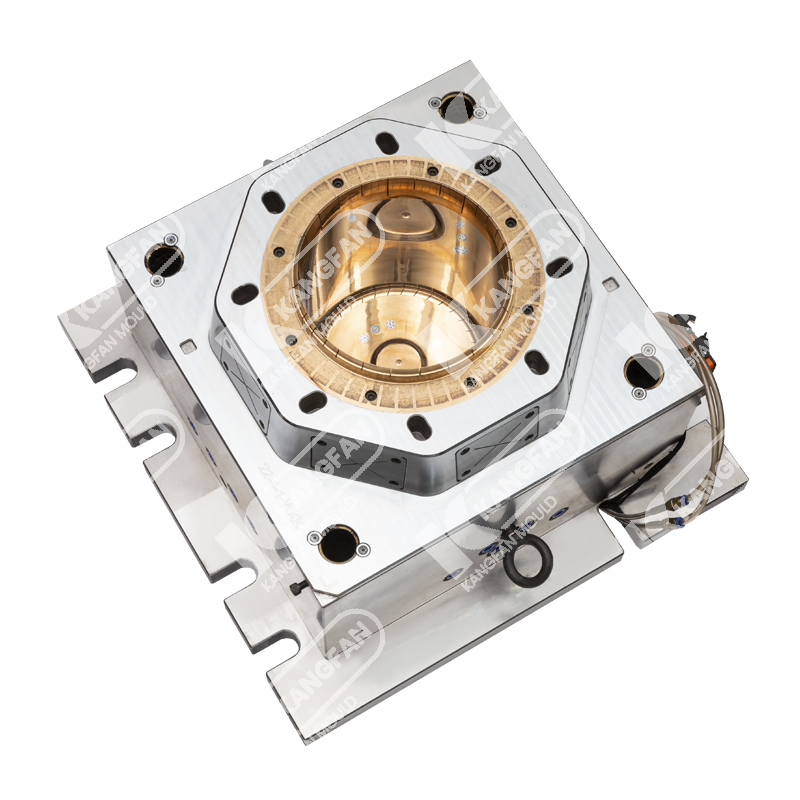

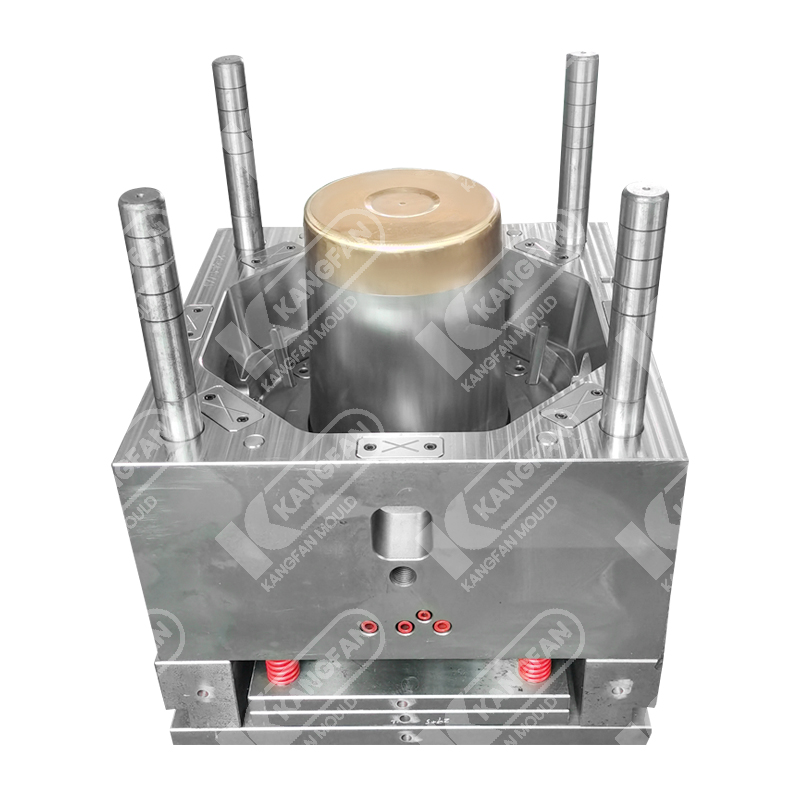

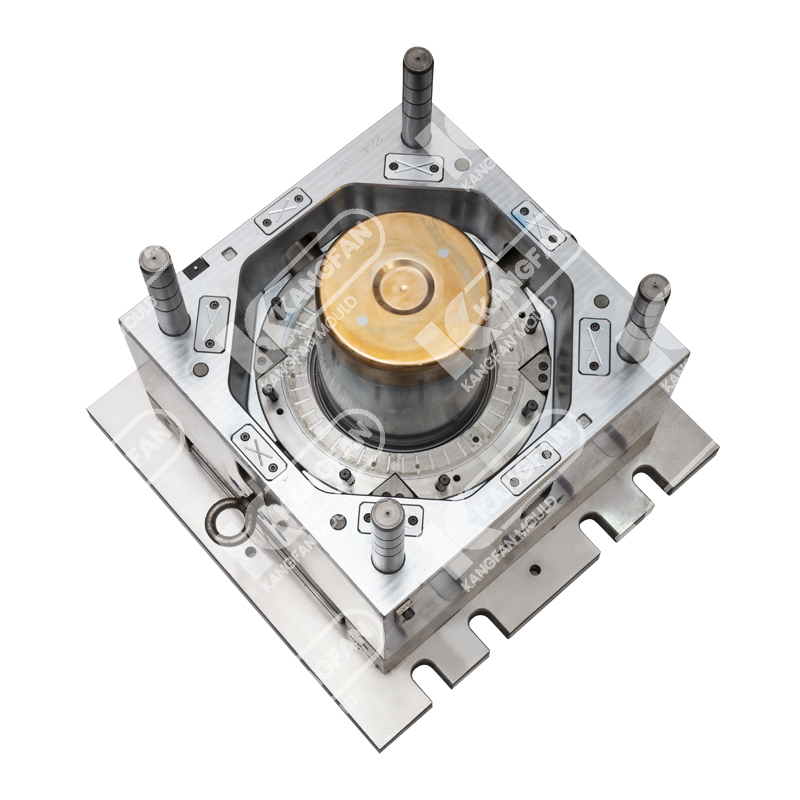

Paint bucket moulding is an important aspect of the manufacturing process for paint containers. Innovations in design and technology have led to advancements in paint bucket moulding, improving functionality, durability, and aesthetics. Here are some of the latest trends in paint bucket moulding:

Material Selection: Traditionally, paint buckets were made from metal or standard plastic materials. However, there has been a shift towards using high-density polyethylene (HDPE) and polypropylene (PP) for their superior durability, chemical resistance, and recyclability. These materials offer better protection against moisture, UV rays, and chemical reactions, ensuring the paint remains in good condition for longer periods.

Eco-Friendly Solutions: Sustainability has become a key focus in the paint industry. As a result, there is a growing demand for eco-friendly paint bucket moulding solutions. Manufacturers are exploring options such as bio-based plastics, recycled materials, and biodegradable additives to reduce the environmental impact of paint packaging. These innovations aim to minimize waste and promote a circular economy.

Improved Design and Functionality: Paint bucket moulds are being designed with improved functionality and user convenience in mind. Features such as ergonomic handles, pour spouts, and snap-on lids are becoming more common. These design elements make it easier for painters to carry, pour, and store paint, enhancing the overall user experience.

Customization and Branding: Paint manufacturers are increasingly recognizing the importance of branding and product differentiation. Advanced moulding techniques allow for the incorporation of customized logos, labels, and embossed designs on paint buckets. This enables paint companies to create unique packaging that aligns with their brand image and helps their products stand out on store shelves.

Tamper-Proofing and Safety: To ensure product integrity and customer safety, paint bucket moulding includes features like tamper-evident seals and child-resistant closures. These additions provide an extra layer of protection, preventing unauthorized access and reducing the risk of accidents, especially in households with children.

Stackability and Space Efficiency: Efficient use of space during storage and transportation is a significant consideration in paint bucket moulding. Manufacturers are designing paint buckets with stackable features and nesting capabilities, allowing them to be neatly stored and transported in bulk. This not only optimizes storage space but also reduces shipping costs and improves logistics efficiency.

Anti-Drip and Anti-Spill Designs: Paint bucket moulding now includes innovative designs to minimize spills and drips. Anti-drip rims, pouring lips, and built-in spouts help to control the flow of paint and prevent messes. These features are particularly useful during pouring and transferring paint between containers, reducing waste and enhancing the overall painting experience.

In conclusion, paint bucket moulding has witnessed significant advancements in recent years, driven by the need for durability, sustainability, and improved user experience. The latest trends focus on material selection, eco-friendly solutions, enhanced design and functionality, customization, safety features, space efficiency, and anti-drip designs. These innovations contribute to a more efficient, user-friendly, and environmentally conscious paint packaging industry.

中文简体

中文简体 English

English

.jpg)