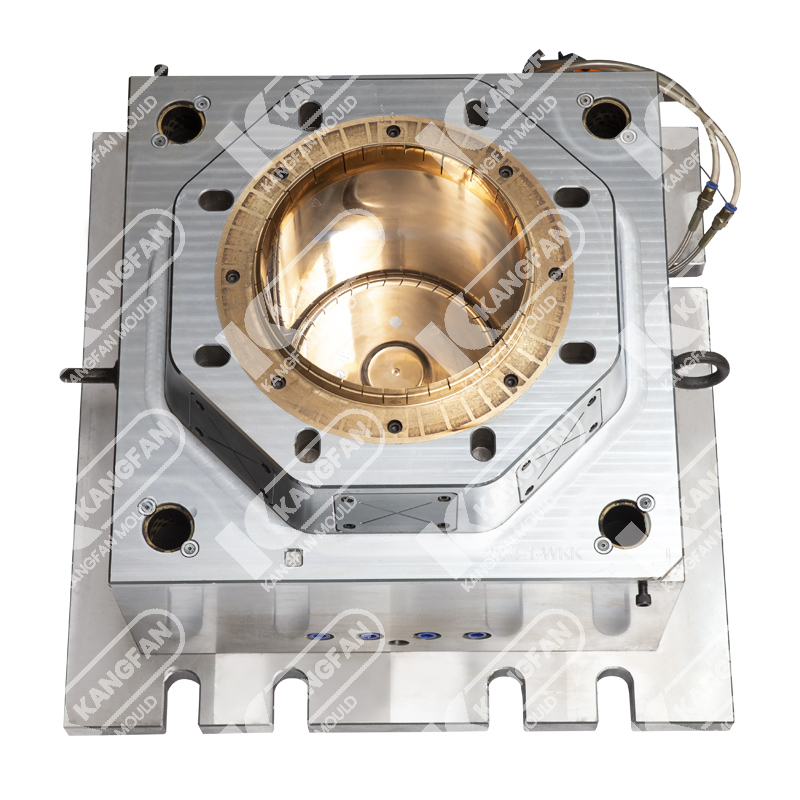

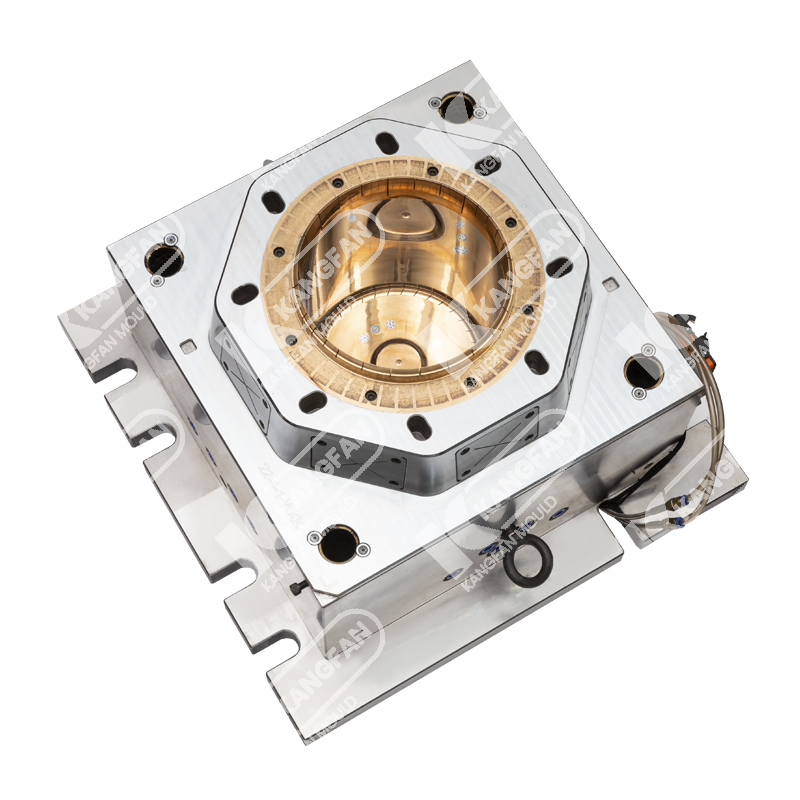

In the dynamic world of mold engineering, the 3.8L Paint Bucket Mould and Round Plastic Bucket Mould have emerged as cornerstones of precision craftsmanship, driving advancements in the packaging industry. As manufacturers strive for excellence, these molds play a pivotal role in shaping the future of container production, offering versatility, durability, and efficiency.

3.8L Paint Bucket Mould: A Canvas for Creativity

1. Capacity and Convenience: The 3.8L Paint Bucket Mould is engineered to perfection, creating containers that strike a balance between optimal capacity and user convenience. This mold's ability to produce paint buckets of standardized size caters to the needs of industries where consistency is paramount.

2. Material Innovation: Crafted with precision, the 3.8L Paint Bucket Mould accommodates a variety of materials, including high-density polyethylene (HDPE) and polypropylene (PP). This versatility allows manufacturers to meet diverse requirements in terms of strength, durability, and chemical resistance for the containment of various paint formulations.

3. Tamper-Evident Features: Security in packaging is crucial, and the 3.8L Paint Bucket Mould often incorporates tamper-evident features. From secure lid seals to specialized closures, these features ensure the integrity of the paint within, meeting industry standards and consumer expectations.

4. Stackability and Storage Efficiency: Designed with an eye on practicality, the 3.8L Paint Bucket Mould creates containers that are stackable, optimizing storage space during transportation and warehousing. This feature contributes to logistical efficiency and cost-effectiveness for both manufacturers and end-users.

5. Customization Potential: The 3.8L Paint Bucket Mould is not just a tool for mass production; it's a canvas for creativity. Manufacturers can customize the mold to incorporate branding elements, labels, or embossing, allowing for brand differentiation in a competitive market.

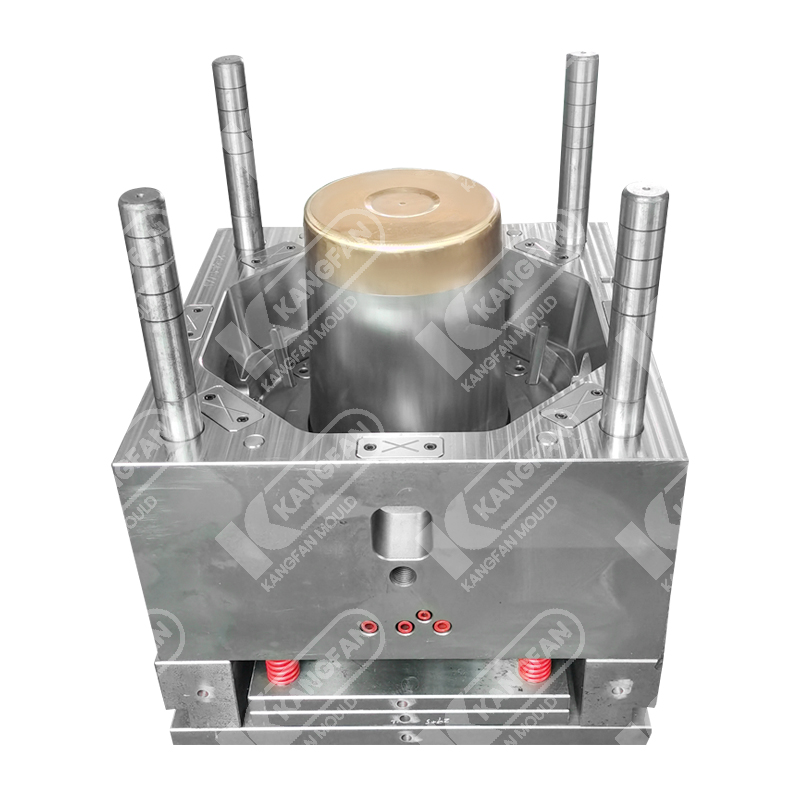

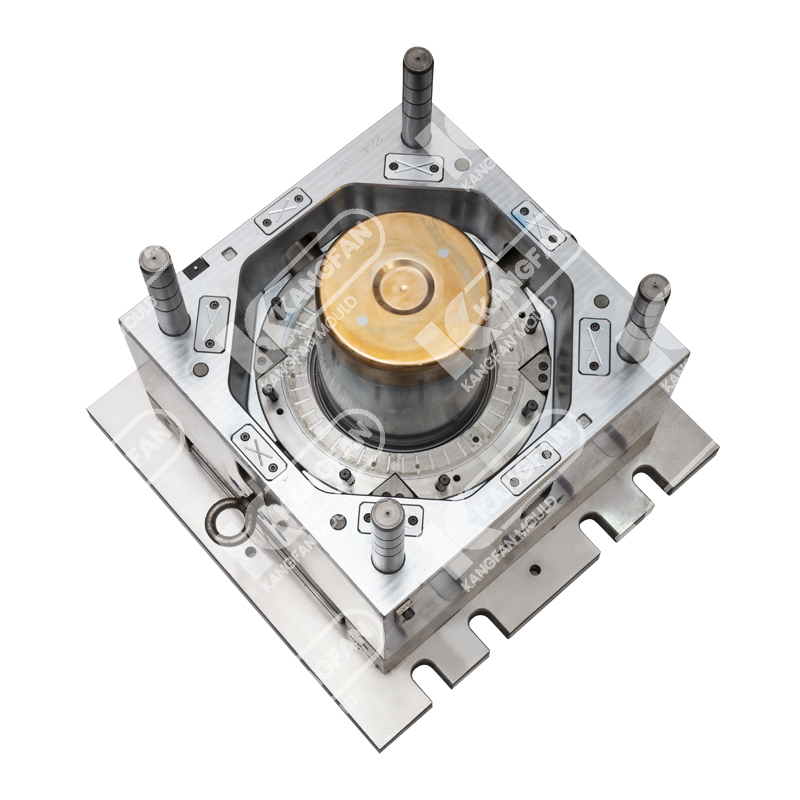

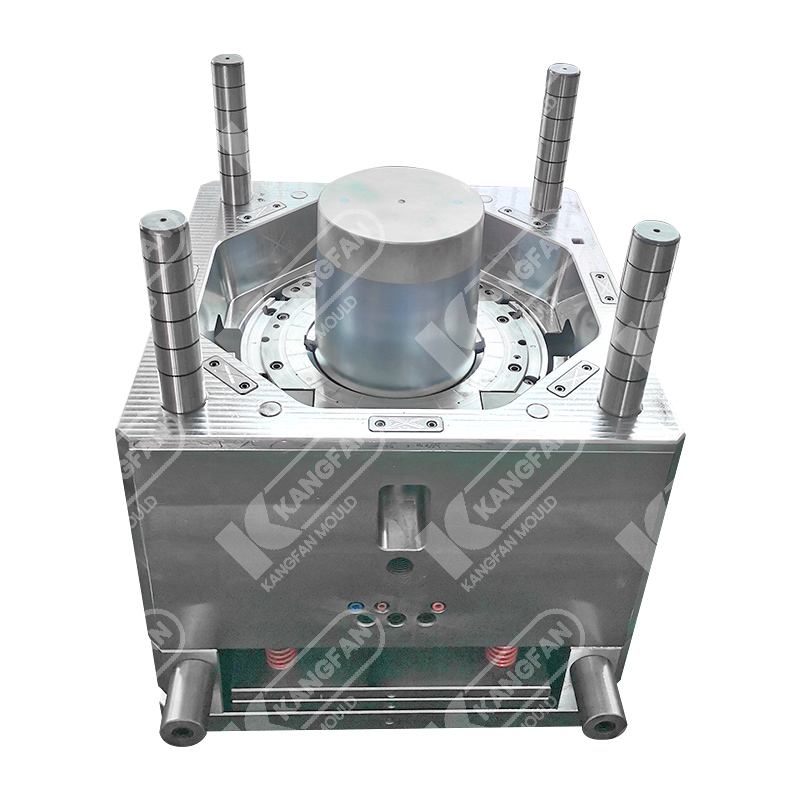

Round Plastic Bucket Mould: Precision in Form and Function

1. Seamless Construction: The Round Plastic Bucket Mould is characterized by its seamless construction, eliminating weak points and enhancing the overall strength and durability of the produced buckets. This structural integrity is critical, especially in industries where the containment of liquids demands a high level of reliability.

2. Consistent Wall Thickness: Precision engineering is at the heart of the Round Plastic Bucket Mould, ensuring consistent wall thickness in every produced bucket. This uniformity is essential for maintaining the integrity of the bucket's structure and contributes to its overall robustness.

3. Enhanced Aesthetics: The round shape is not just a functional choice but also an aesthetic one. The Round Plastic Bucket Mould produces containers with a visually appealing and classic silhouette, making these buckets suitable for a wide range of applications, from industrial use to retail packaging.

4. Easy Demolding and Ejection: Efficiency in the manufacturing process is a priority, and the Round Plastic Bucket Mould is designed for easy demolding and ejection. This feature not only speeds up the production cycle but also reduces the risk of defects and ensures a high-quality end product.

5. Compatibility with Various Plastics: To meet the diverse needs of manufacturers, the Round Plastic Bucket Mould is compatible with various plastic materials, including polyethylene (PE) and polypropylene (PP). This flexibility enables the production of buckets tailored to specific industry requirements.

Driving Innovation in the Mold Industry

1. Industry 4.0 Integration: Both the 3.8L Paint Bucket Mould and the Round Plastic Bucket Mould are at the forefront of Industry 4.0 integration. Smart manufacturing technologies, including real-time monitoring and data analytics, are being incorporated into these molds to enhance efficiency, reduce downtime, and optimize production processes.

2. Sustainability Initiatives: In response to the growing emphasis on sustainability, manufacturers are integrating eco-friendly practices into the production of these molds. From the use of recycled materials to energy-efficient manufacturing processes, the molds are evolving to align with global sustainability goals.

3. Precision Tooling: The demand for precision in molding technology is driving advancements in tooling design. Molds are now equipped with precision inserts and interchangeable components, allowing for quick adjustments and reducing lead times in the production of both 3.8L paint buckets and round plastic buckets.

4. Collaborative Design Approaches: As customization becomes a key differentiator, mold manufacturers are increasingly adopting collaborative design approaches. Working closely with clients, they tailor the 3.8L Paint Bucket Mould and Round Plastic Bucket Mould to specific requirements, ensuring that the end product aligns with the unique needs of each industry.

5. Quality Assurance Protocols: Rigorous quality assurance protocols are integral to the manufacturing of these molds. From advanced testing techniques to in-process inspections, manufacturers are committed to delivering molds that meet or exceed industry standards, ensuring the longevity and reliability of the produced containers.

In conclusion, the 3.8L Paint Bucket Mould and Round Plastic Bucket Mould stand as exemplars of precision engineering, driving innovation in the mold industry. As these molds continue to evolve, they pave the way for enhanced efficiency, sustainability, and versatility in the production of containers that serve diverse industries around the globe. Whether containing paints, chemicals, or other liquids, these molds are at the forefront of shaping the future of packaging solutions.

中文简体

中文简体 English

English

.jpg)