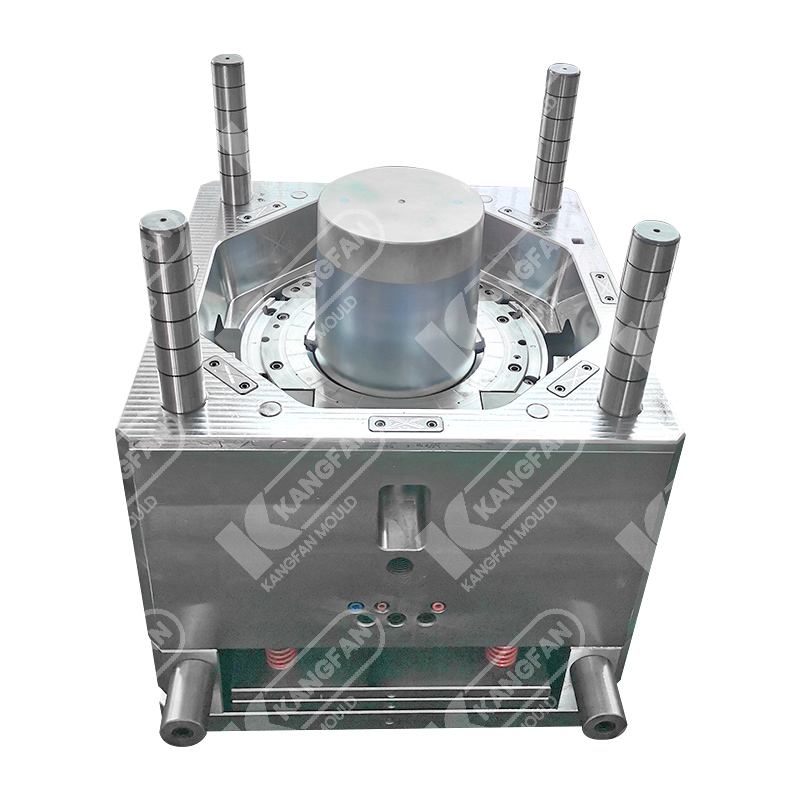

Introduce High Quality Thickened Plastic Drum And Paint Pail Mould For Multiple Uses

Supply Thickened Plastic Drum Paint Pail Mould Manufacturers In China

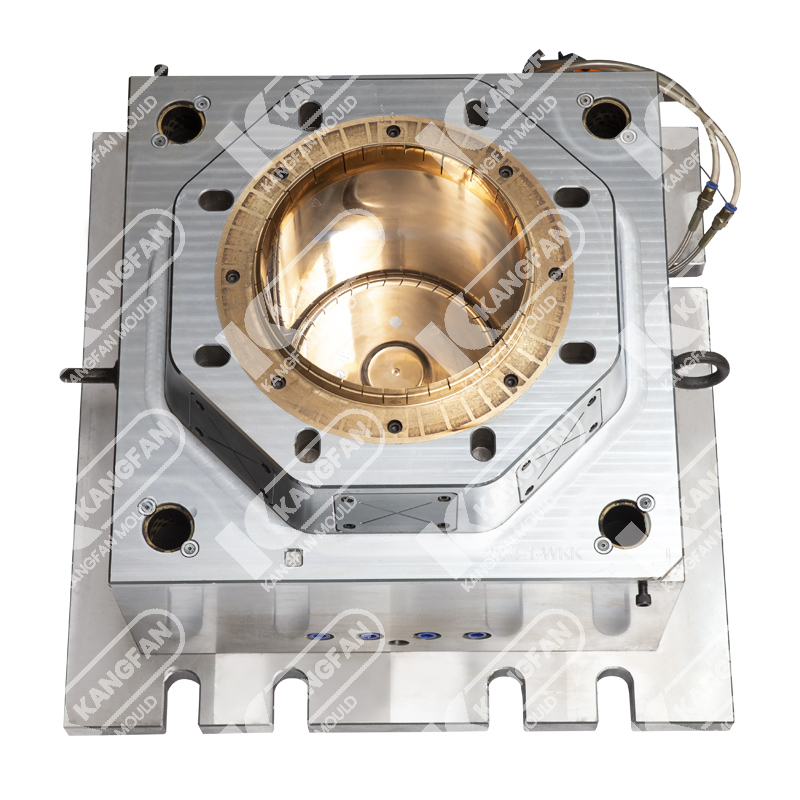

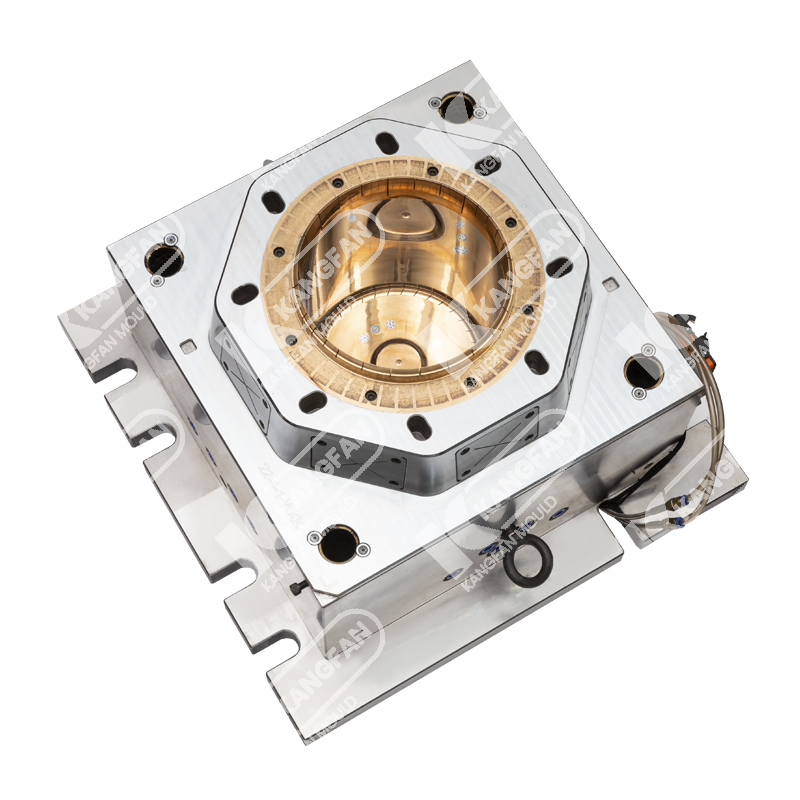

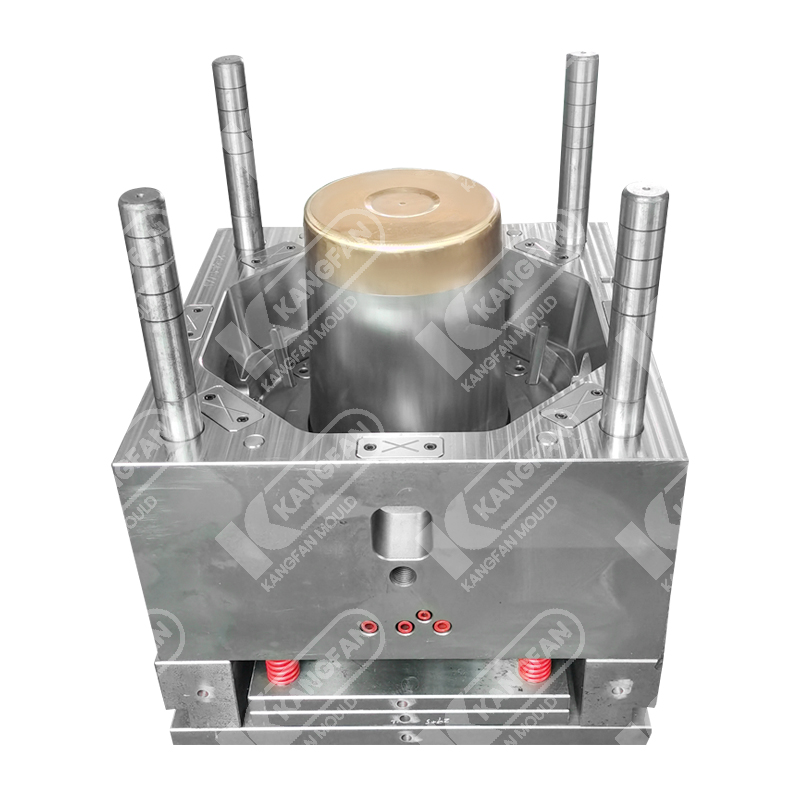

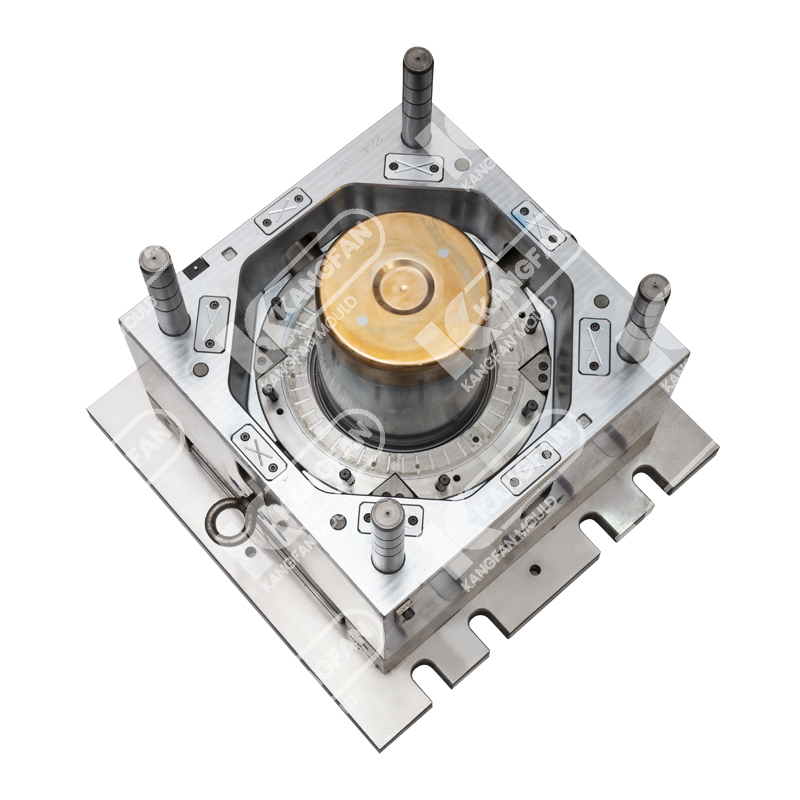

The Thickened plastic drum mould and Paint pail mould are two innovative and essential products in the field of plastic manufacturing. These molds are specifically designed to produce high-quality and durable plastic drums and paint pails, addressing the needs of various industries such as chemical storage, paint production, and transportation. With advanced technology and good materials, these molds offer good performance and reliability, making them the preferred choice for many manufacturers worldwide.

The Thickened plastic drum mould stands out for its features that ensure the production of robust and long-lasting plastic drums. Firstly, this mold is manufactured with precision using high-grade steel, ensuring enough strength and durability. The thickness of the mold guarantees the structural integrity of the final product, allowing it to withstand the rigorous demands of storage and transportation.

Customizable Options for Thickened plastic drum mould. The mould can be customized according to specific requirements, including size, shape, and color. This flexibility allows businesses to create mould that matches their branding and functional needs.

Additionally, the Thickened plastic drum mould is designed to offer good dimensional accuracy, resulting in consistently uniform drum sizes. This ensures compatibility with standard drum handling equipment and facilitates smooth integration into existing logistics and supply chain systems. The advanced cooling system incorporated within the mold ensures efficient and fast cycle times, increasing productivity and reducing manufacturing costs.

The mold is also equipped with an innovative ejection system that allows for easy removal of the plastic drum, reducing the risk of damage or deformation. This, combined with the smooth surface finish of the mold, ensures a final product that meets high-quality standards. With this feature, the producer can pay less attention to the production process.

The Paint pail mould is another indispensable tool for manufacturers in the paint industry. This mold is specifically designed to produce paint pails with superior strength, leak-proof properties, and exceptional aesthetics. The use of high-quality steel in the manufacturing process ensures the durability and reliability of the mold, allowing for multiple production cycles without compromising the quality of the final product.

The design of the Paint pail mould is optimized to produce paint pails with accurate capacity measurements, ensuring precise batching and consistent quality control. The mold is also equipped with a unique locking mechanism that guarantees tight sealing and prevents any leakage during storage or transportation. It can withstand high pressures and hard temperatures, making it an ideal choice for storing different types of paints and chemicals.

The mould can be customized to accommodate different types of paints, including water-based, oil-based, and solvent-based paints. It allows paint manufacturers to produce pails suitable for a wide range of products, ensuring versatility and convenience.

Furthermore, the Paint pail mould incorporates advanced venting and cooling systems, allowing for efficient and rapid production cycles. The excellent surface finish of the mold ensures a smooth and glossy appearance of the paint pails, enhancing their market appeal and brand image.

The Thickened plastic drum mould and Paint pail mould are good products that meet the diverse needs of the plastic manufacturing industry. With their features, these molds guarantee the production of robust, leak-proof, and aesthetically pleasing plastic drums and paint pails. The durability, precision, and efficiency of these molds make them indispensable tools for manufacturers worldwide. By choosing these high-quality molds, manufacturers can enhance their production processes, reduce manufacturing costs, and improve customer satisfaction.

中文简体

中文简体 English

English

.jpg)