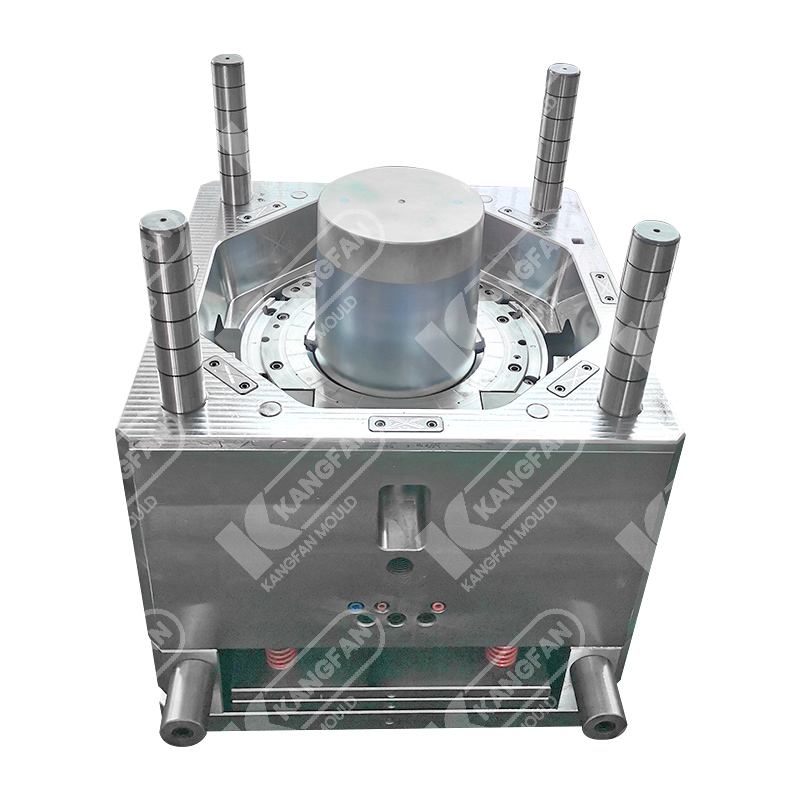

A lubrication oil bucket mold, also known as a lubricant oil bucket mold, is a specialized mold used in the manufacturing process of plastic lubrication oil buckets. The characteristics of such a mold include:

-

Material: Lubrication oil bucket molds are typically made from high-quality and durable materials, such as steel or aluminum. These materials ensure the mold's strength, longevity, and resistance to wear and tear.

-

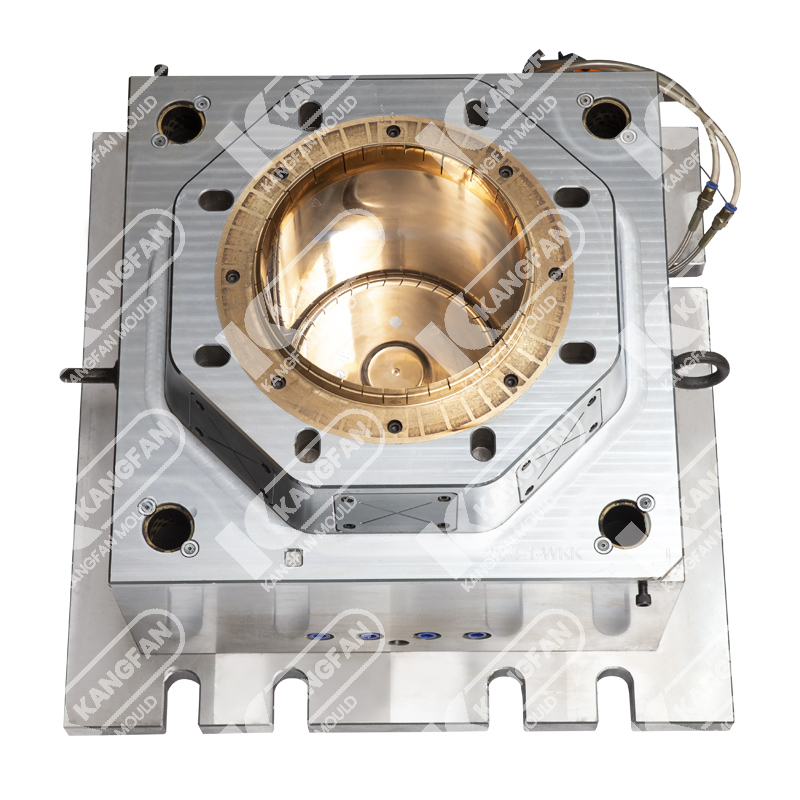

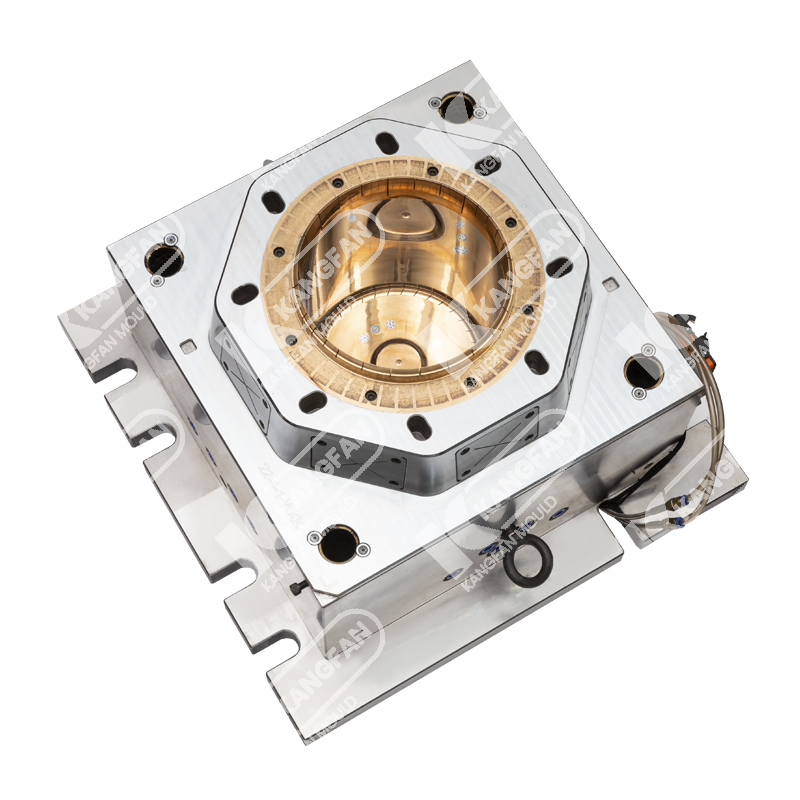

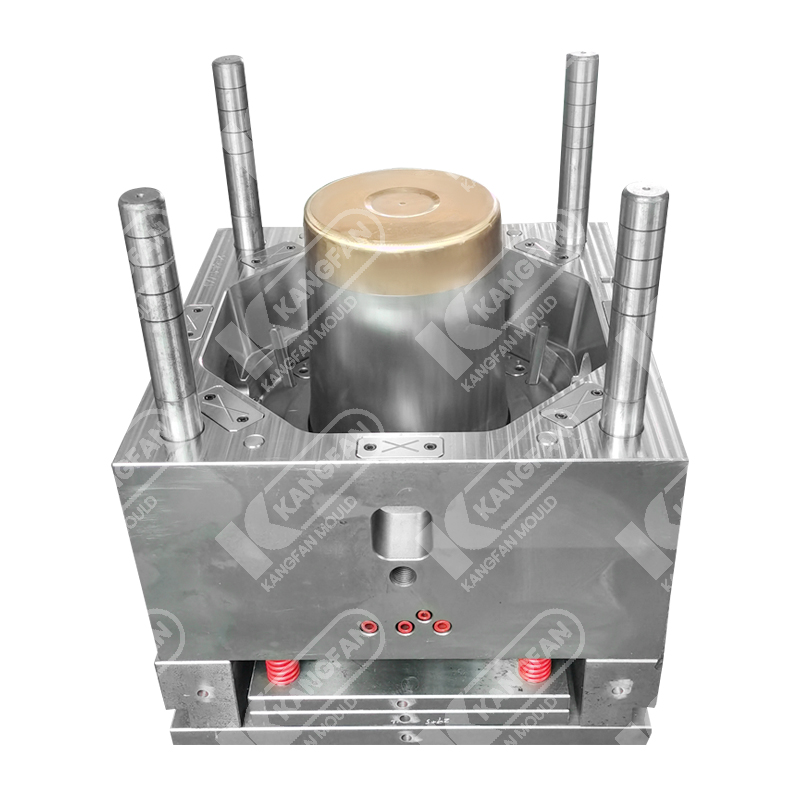

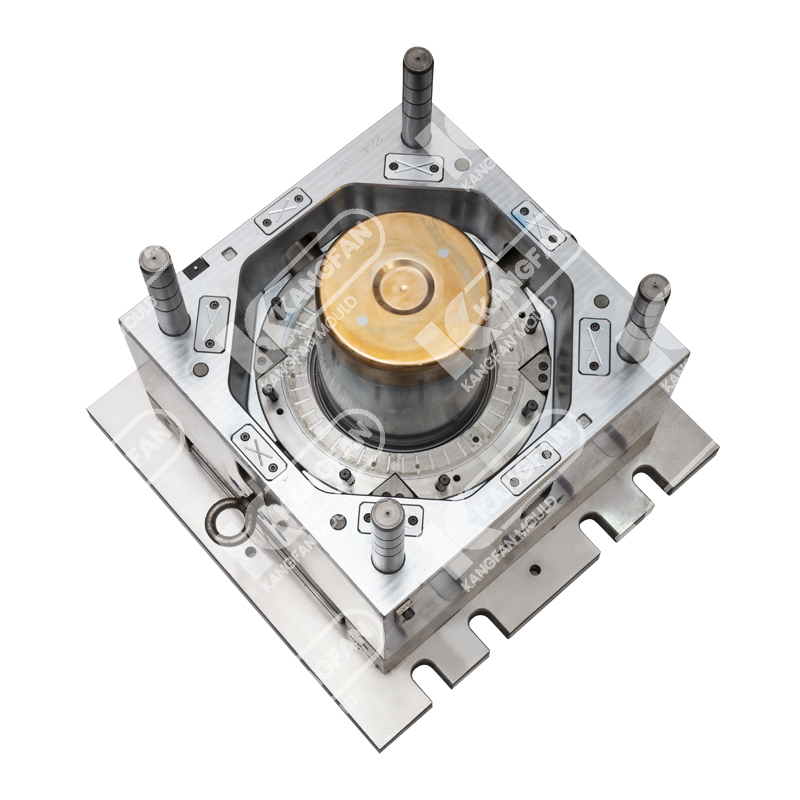

Mold Cavity and Core: The mold consists of two main parts: the cavity and the core. The cavity defines the external shape and features of the lubrication oil bucket, while the core creates the internal shape and details. Both parts work together to form the desired product shape.

-

Injection Molding: Lubrication oil bucket molds are designed for injection molding processes. Molten plastic material, such as polyethylene (PE) or polypropylene (PP), is injected into the mold cavity under high pressure and temperature. The mold then cools and solidifies the plastic, forming the lubrication oil bucket.

-

Mold Design and Precision: The mold design is crucial for achieving the desired shape, dimensions, and functionality of the lubrication oil bucket. Molds need to be precisely engineered to ensure accurate and consistent production. This includes features such as draft angles, parting lines, and gating systems.

-

Cooling System: Efficient cooling is essential for the proper solidification of the plastic material within the mold. Lubrication oil bucket molds typically incorporate a cooling system, such as water channels or baffles, to ensure uniform cooling and reduce cycle times.

-

Ejection System: Once the plastic has solidified, the lubrication oil bucket needs to be ejected from the mold. The mold features an ejection system, which may include ejector pins or plates, to push the finished product out of the mold cavity.

-

Surface Finish: The surface finish of the lubrication oil bucket mold is critical for achieving a smooth and defect-free product. Molds are carefully polished and treated to minimize surface imperfections and ensure the production of high-quality lubrication oil buckets.

-

Mold Maintenance: Lubrication oil bucket molds require regular maintenance and cleaning to ensure their optimal performance and longevity. This includes cleaning any residue or buildup, inspecting and repairing any damaged parts, and lubricating moving components.

It's important to note that the specific characteristics of a lubrication oil bucket mold may vary depending on the manufacturer's specifications, the desired bucket design, and the production requirements. Therefore, it is advisable to consult the manufacturer or mold supplier for detailed information on a particular mold.

中文简体

中文简体 English

English

.jpg)