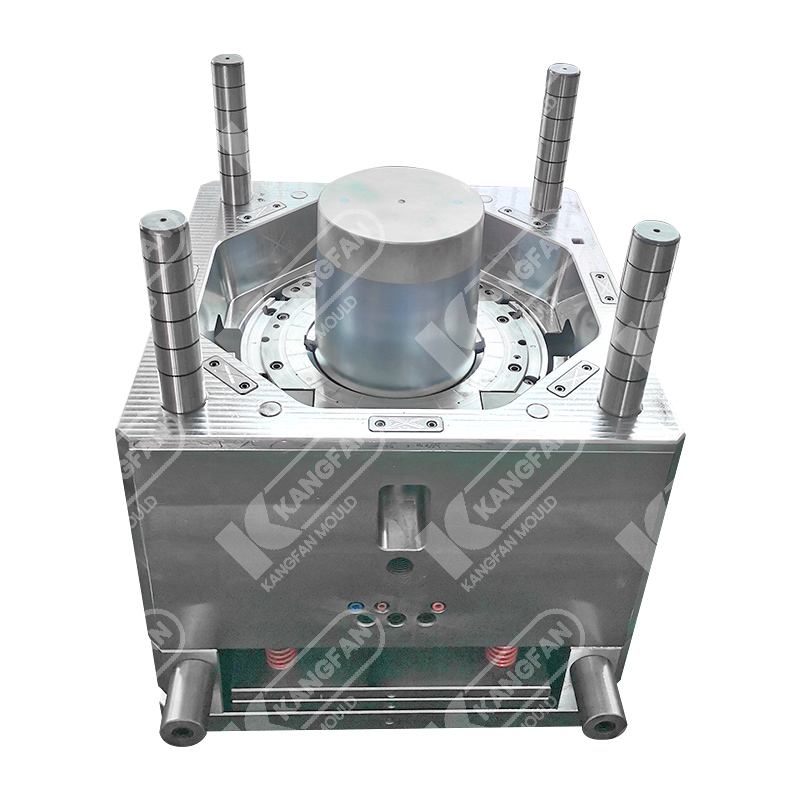

Oil bucket injection mold tub molds are specialized molds used for producing plastic tubs that are typically used for storing and transporting oil or other liquids. The following are some design points that are important to consider when designing oil bucket injection mold tub molds:

-

Material Selection: The material used to make the mold should be able to withstand the high temperatures and pressures involved in the injection molding process. Common materials include hardened steel, aluminum, or copper alloys.

-

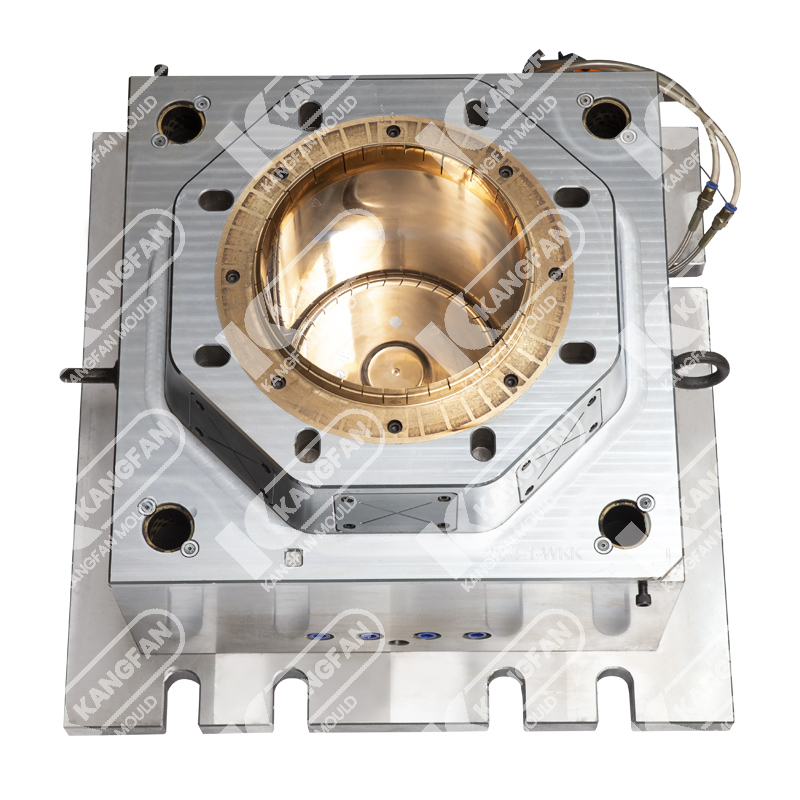

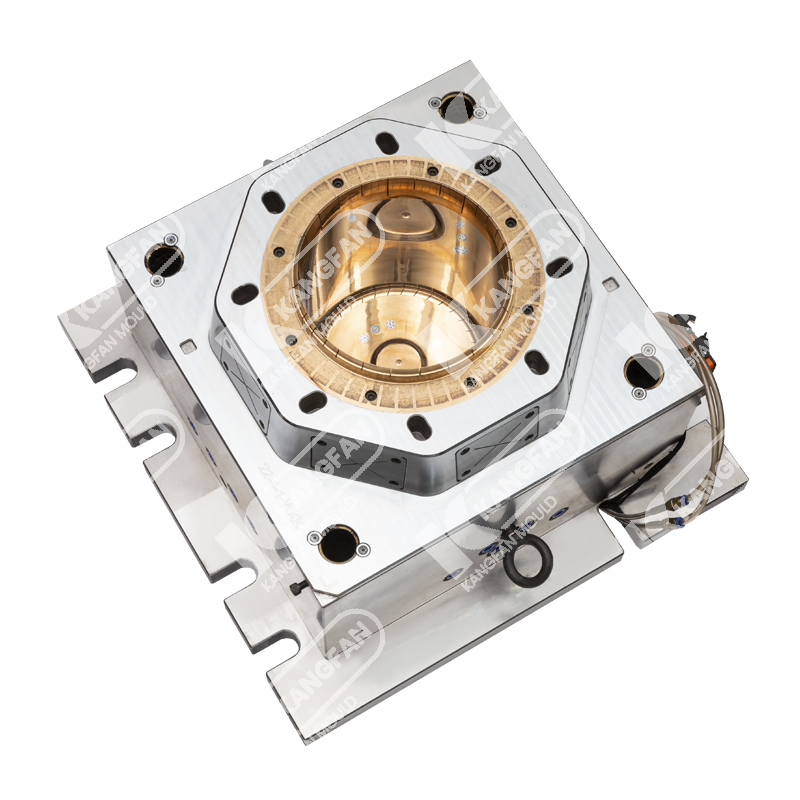

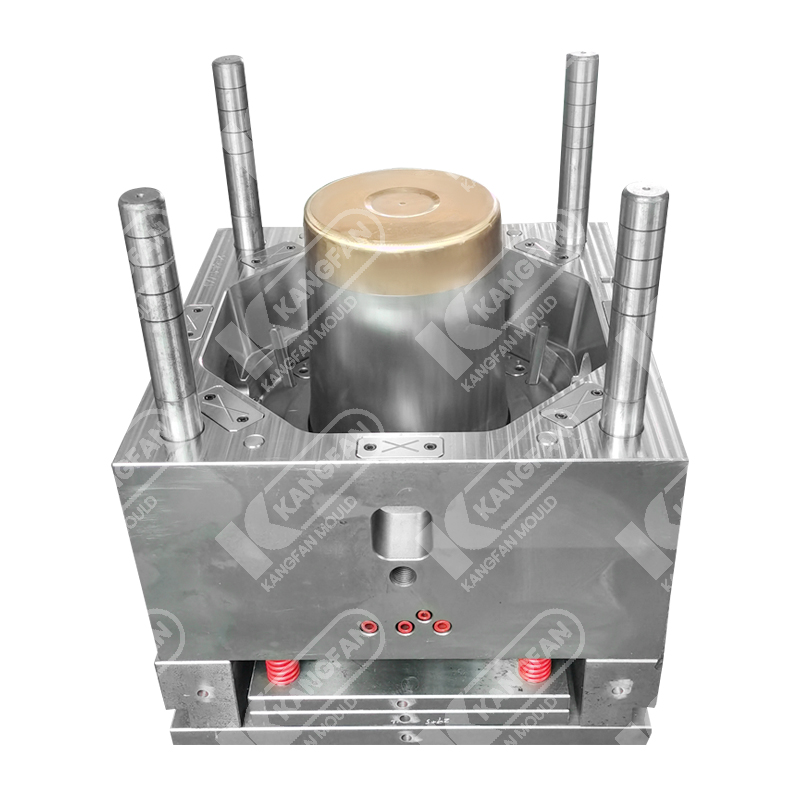

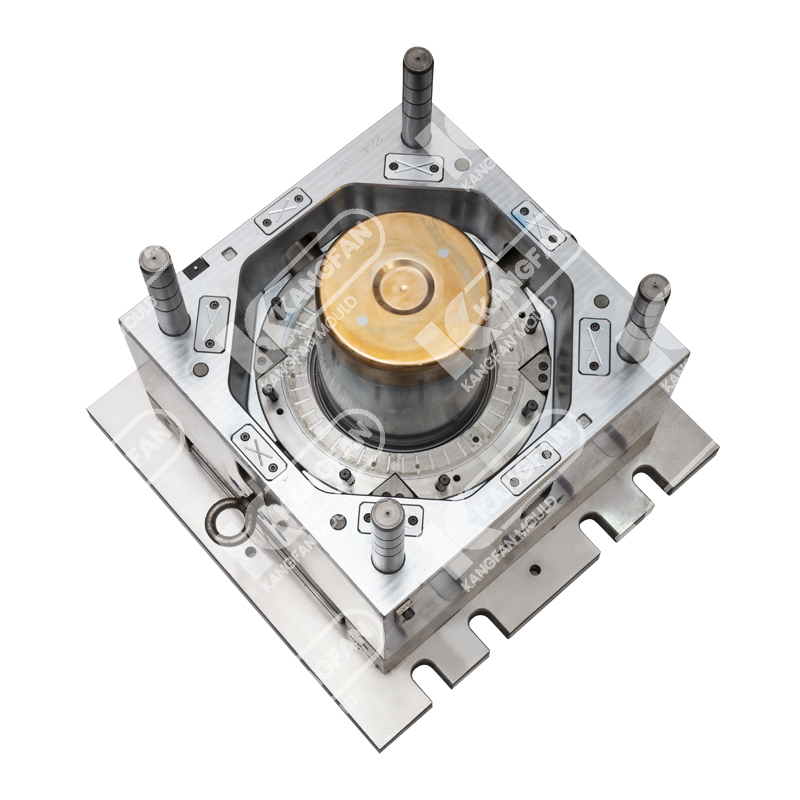

Mold Base Design: The mold base is the foundation of the mold and should be designed for stability and durability. The mold base should be made of high-quality materials and should be designed to accommodate the mold cavities and any necessary cooling channels.

-

Mold Cavity Design: The mold cavity is the part of the mold that defines the shape of the tub. The cavity should be designed to produce a tub that meets the required specifications, such as size, shape, and thickness. The design should also consider any features required, such as handles or spouts.

-

Cooling System Design: The cooling system is an important part of the mold design and should be designed to efficiently cool the mold and the plastic material during the injection molding process. Proper cooling is essential to achieve a high-quality finish and to prevent warping or other defects.

-

Ejection System Design: The ejection system is used to remove the finished tub from the mold. The design should be carefully considered to ensure that the ejection pins do not damage the finished product, and that the ejection system is reliable and efficient.

-

Maintenance Considerations: The mold design should be easy to maintain and repair. The mold should be designed to allow easy access for cleaning and maintenance, and any replaceable components should be easily accessible.

Overall, a well-designed oil bucket injection mold tub mold should be able to produce high-quality plastic tubs that meet the required specifications, are durable, and are easy to maintain and repair.

中文简体

中文简体 English

English

.jpg)