How does the process of pail bucket moulding revolutionize the manufacturing industry?

Let's dive into the fascinating world of pail bucket moulding, my friend! This process has truly revolutionized the manufacturing industry and transformed the way we produce those trusty containers that play a significant role in our daily lives.

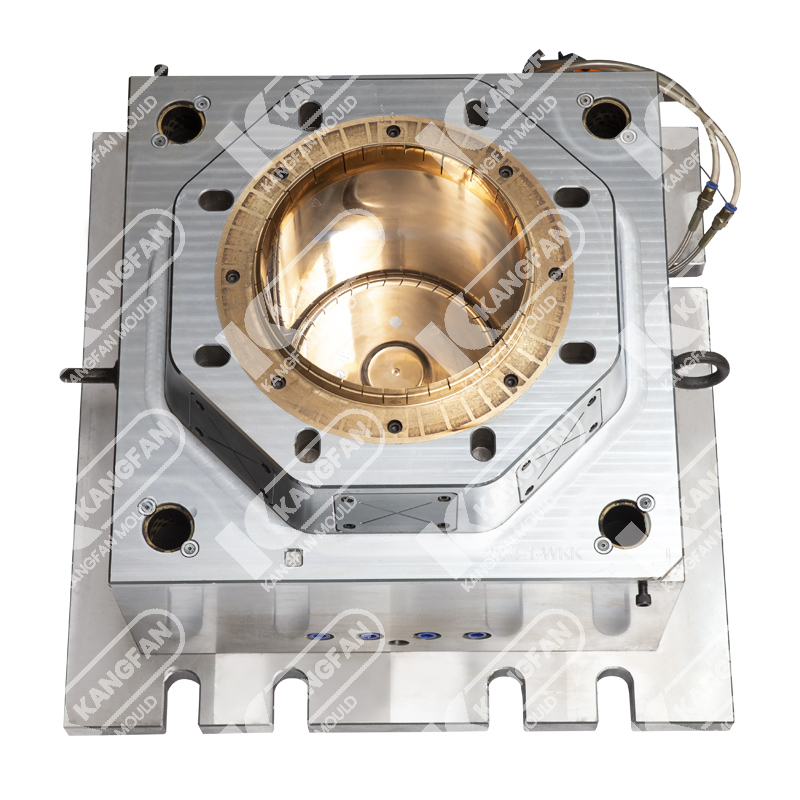

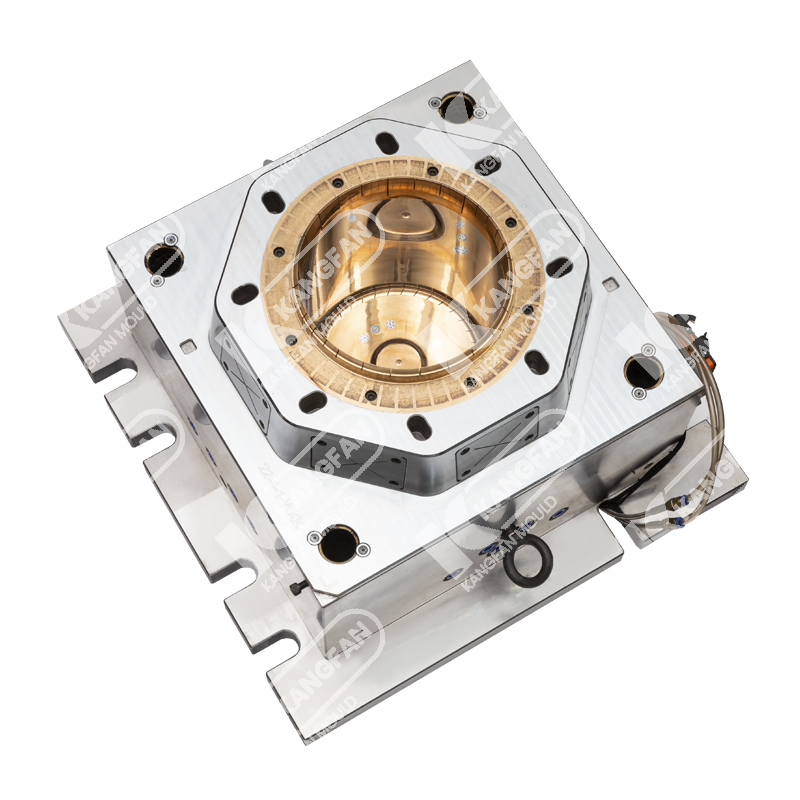

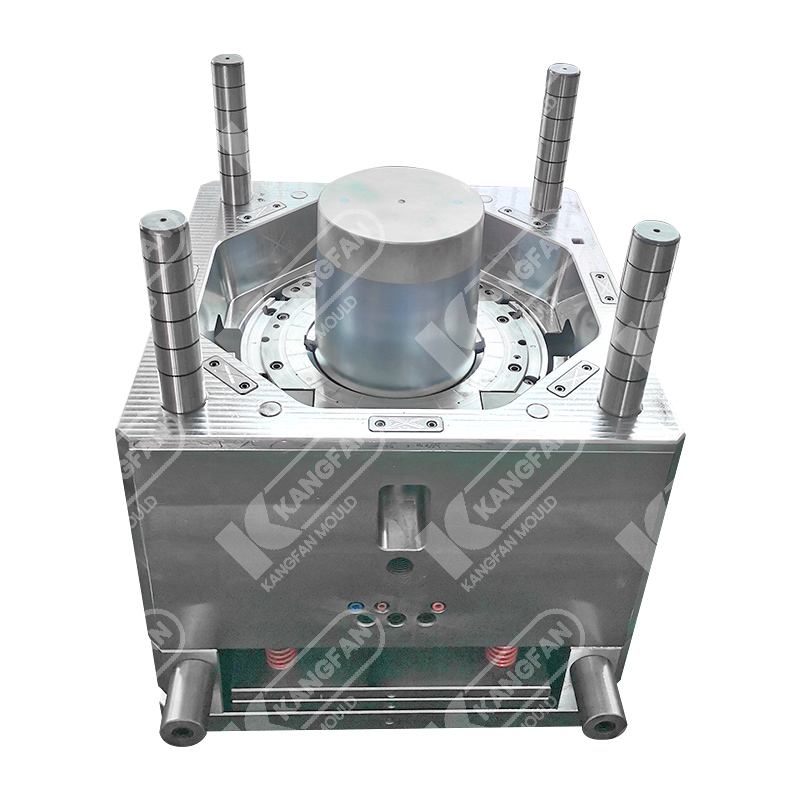

The pail bucket moulding process involves the creation of custom molds specifically designed to shape molten plastic material into the desired pail or bucket form. This innovative approach offers a plethora of advantages that have reshaped the industry landscape. From enhancing the overall durability and quality of the final products to providing a cost-effective and highly customizable solution, pail bucket moulding has become a game-changer.

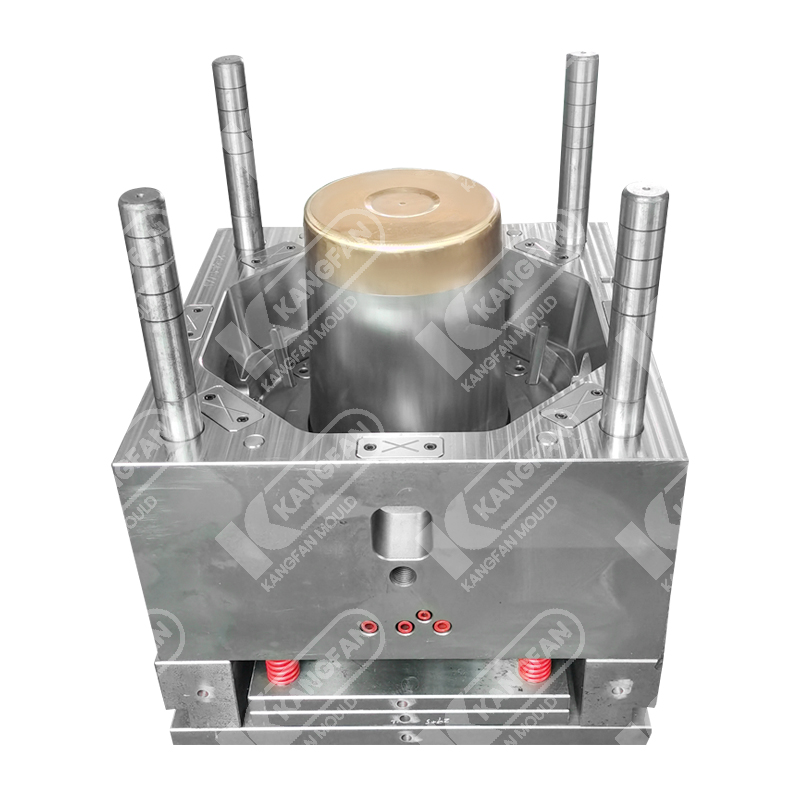

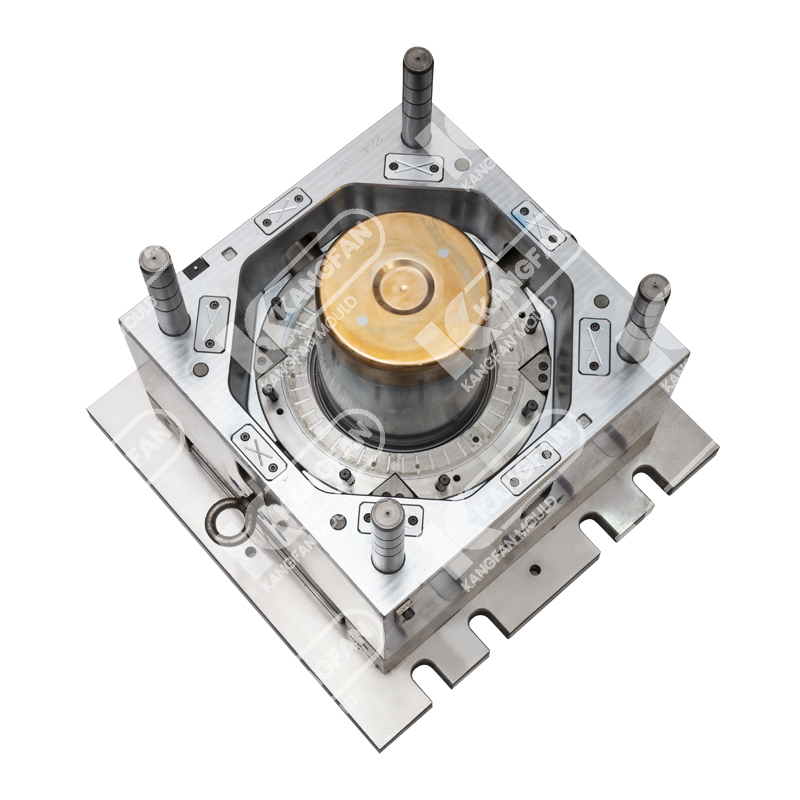

One of the key advantages of pail bucket moulding is its ability to produce incredibly sturdy and long-lasting plastic pails and buckets. The molding process allows for the creation of seamless designs, eliminating the weak points often found in traditional bucket manufacturing methods. This means you won't have to worry about leaks, cracks, or any other issues that could compromise the functionality of your trusty container. Whether it's for carrying construction materials, storing liquids, or even organizing household items, a pail or bucket created through this process offers unmatched durability and reliability.

Cost-effectiveness is another noteworthy aspect of pail bucket moulding. The ability to create custom molds means that manufacturers can optimize their production processes, reducing material waste and achieving greater efficiency. The result? A more cost-effective solution that benefits both the manufacturer and the end consumer. Additionally, the scalability of the process allows for efficient mass production while maintaining consistent quality throughout the production run.

Furthermore, pail bucket moulding offers a wide range of customization options, allowing for the creation of containers tailored to specific requirements and brand aesthetics. Whether it's selecting the size, color, handle design, or adding custom logos or labels, the possibilities are endless. This flexibility enables businesses to showcase their unique identity while meeting the specific needs of their customers.

Now, let's talk about the materials used in pail bucket moulding. High-density polyethylene (HDPE), polypropylene (PP), and other plastic polymers are commonly used in this process due to their excellent strength, chemical resistance, and versatility. These materials ensure that the final pails and buckets can withstand various environmental conditions, making them suitable for diverse applications ranging from construction and agriculture to food and beverage industries.

What's remarkable about pail bucket moulding is its ability to mold complex shapes, intricate designs, and functional features seamlessly. From reinforced handles and pour spouts to embossed patterns and measurement markings, manufacturers can incorporate a variety of elements to make the containers more user-friendly and practical. This attention to detail sets pail bucket moulding apart from other manufacturing methods and elevates the overall user experience.

The combination of strength, customization options, and cost-effectiveness makes pail bucket moulding an incredibly versatile solution for a wide range of industries. Whether you need sturdy containers for transport and storage, reliable tools for work or leisure, or even branded merchandise, pail bucket moulding has got you covered.

In conclusion, pail bucket mould manufacturers have revolutionized the manufacturing industry, providing an efficient, cost-effective, and highly customizable solution to produce durable and versatile plastic pails and buckets. With its ability to create seamless designs, optimize production processes, and cater to specific requirements, this innovative process has earned its rightful place as a cornerstone of modern manufacturing. So, next time you reach out for that trusty pail or bucket, take a moment to appreciate the incredible journey it had gone through -- starting as molten plastic material shaped by the power of pail bucket moulding.

中文简体

中文简体 English

English

.jpg)