In the ever-evolving landscape of plastic molding technology, the precision and efficiency of molds play a pivotal role in shaping the manufacturing industry. Two key players in this realm, the Round Plastic Bucket Mould and the Square Plastic Bucket Mould, stand out as exemplars of innovation, meeting diverse industrial needs with their distinct designs. Let's delve into the latest advancements that highlight the capabilities and applications of these molds.

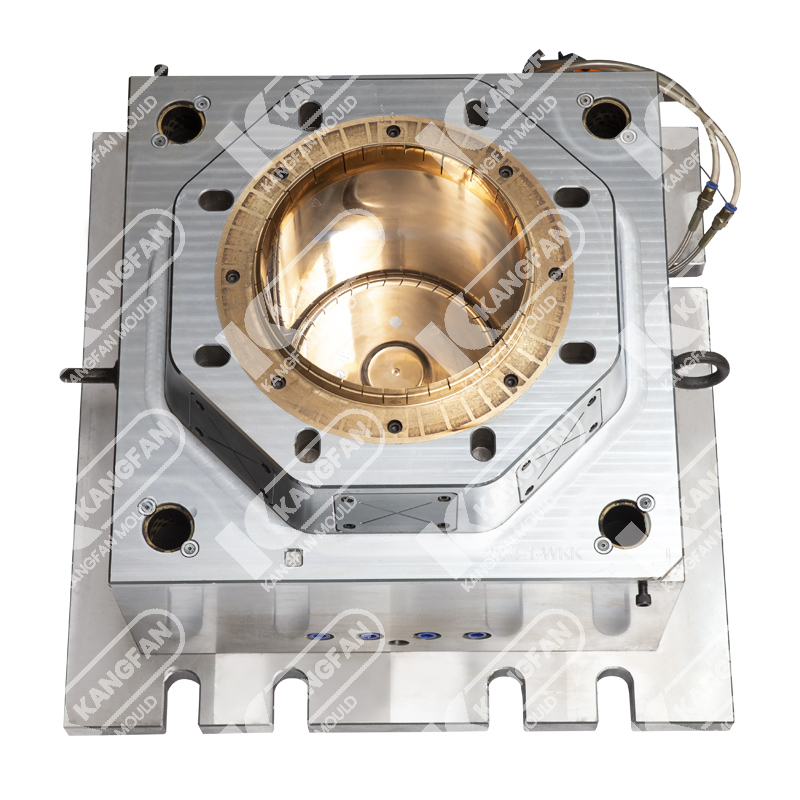

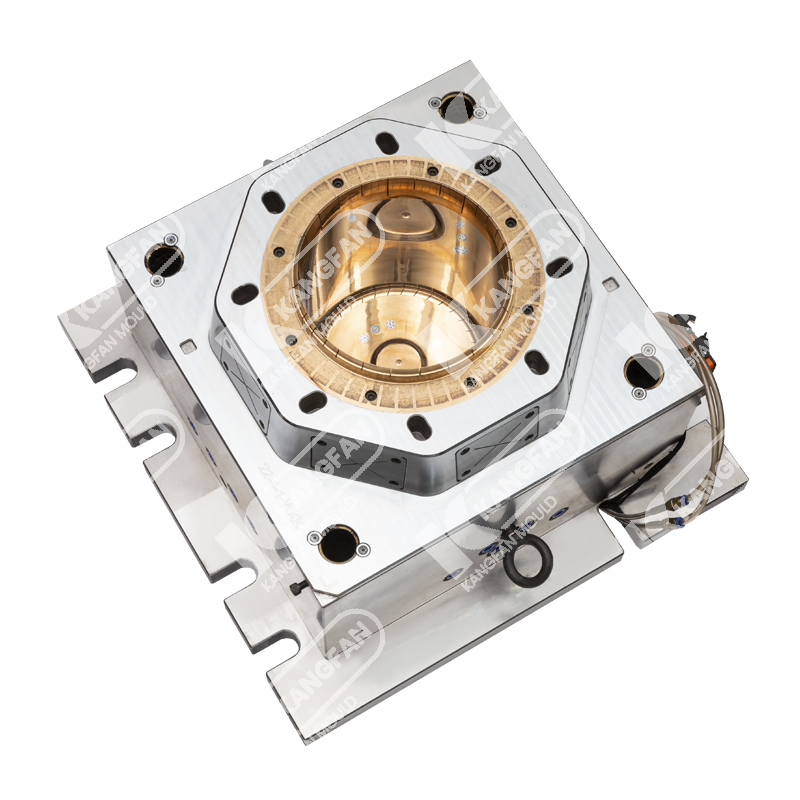

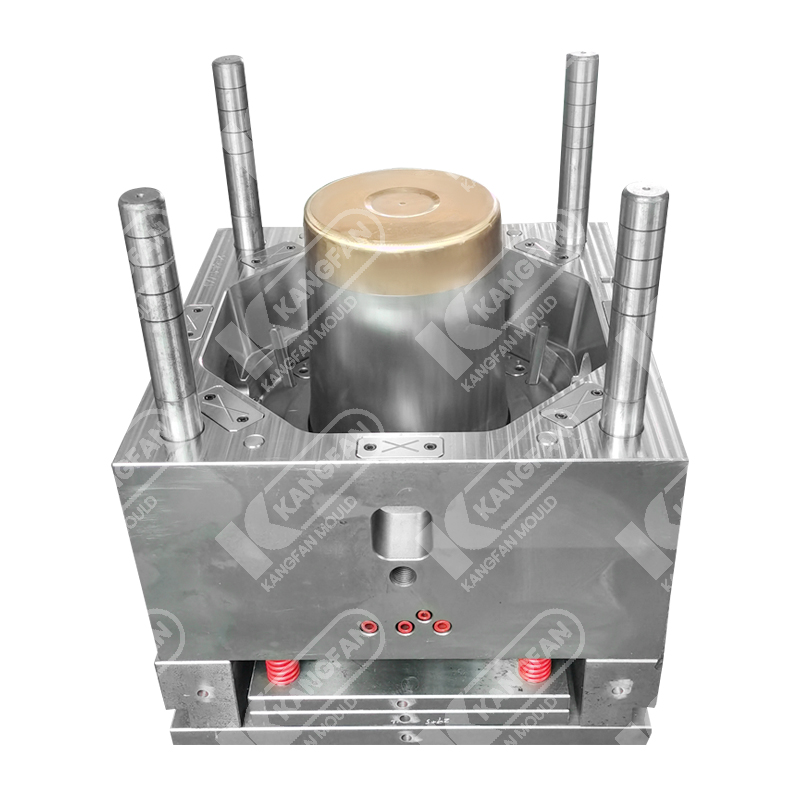

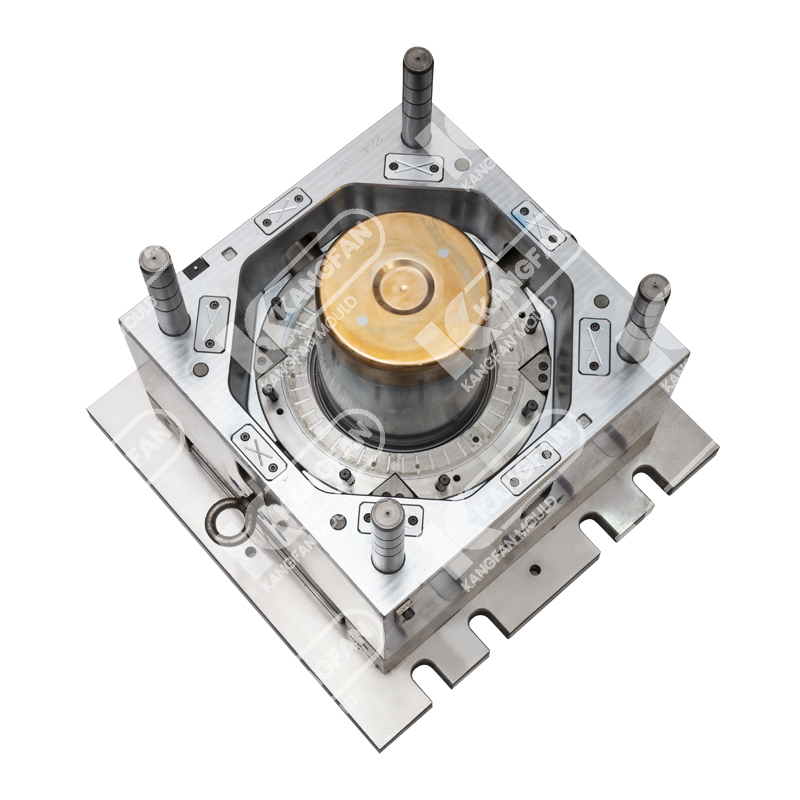

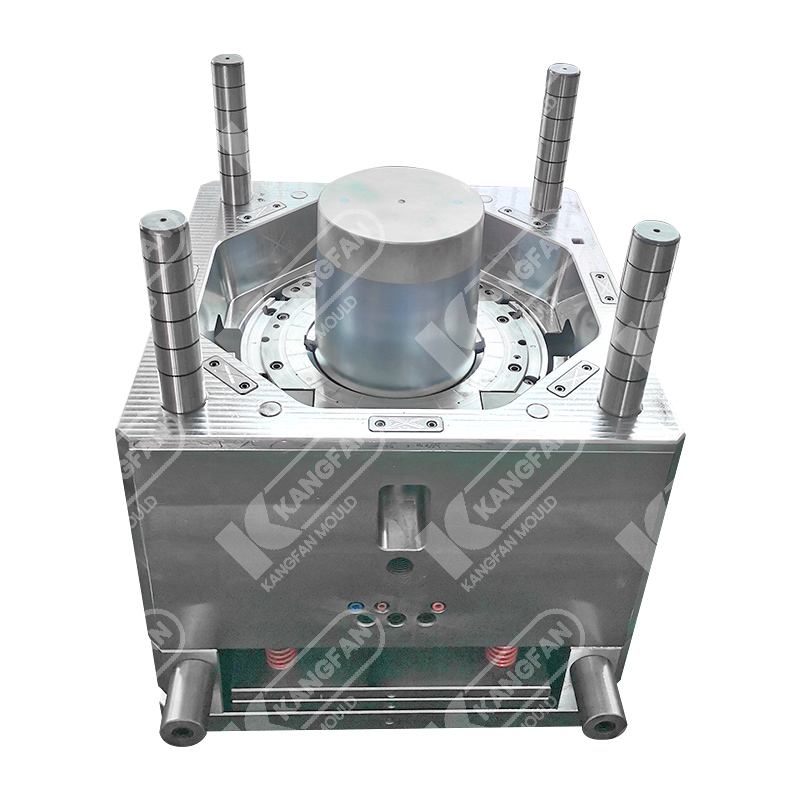

Round Plastic Bucket Mould: The Pinnacle of Circular Precision

Precision Engineering for Seamless Rounds:

Round Plastic Bucket Moulds have long been synonymous with seamless circular designs. The precision engineering behind these molds ensures that every plastic bucket produced maintains a consistent and flawless round shape. This is crucial for industries where cylindrical containers are a preferred choice for storage and transport.

Optimized Material Distribution:

One of the key features of Round Plastic Bucket Moulds lies in their ability to optimize material distribution during the molding process. This not only minimizes material waste but also enhances the structural integrity of the finished product, resulting in robust and reliable plastic buckets.

Versatility in Size and Capacity:

Manufacturers of Round Plastic Bucket Moulds recognize the need for versatility. These molds are designed to accommodate a wide range of sizes and capacities, catering to industries with diverse storage requirements. From small containers to large industrial buckets, the round design remains a constant, ensuring efficiency in production.

Enhanced Cooling Systems for Efficient Production:

Efficient cooling is essential in plastic molding, and Round Plastic Bucket Moulds integrate advanced cooling systems. This not only accelerates the production cycle but also contributes to the overall quality of the molded buckets, reducing the likelihood of defects.

Innovative Ejection Mechanisms:

Ejecting molded buckets seamlessly is critical for productivity, and Round Plastic Bucket Moulds incorporate innovative ejection mechanisms. This ensures a smooth and swift release of the finished products, minimizing production downtime and maximizing efficiency.

Square Plastic Bucket Mould: Redefining Storage Geometry

Precision in Squares for Structural Stability:

Square Plastic Bucket Moulds redefine the geometry of plastic buckets, emphasizing the stability and stackability associated with square designs. The precision in crafting these molds ensures that every square bucket maintains its structural integrity, even when stacked, making them ideal for space-efficient storage.

Space Optimization in Storage:

Square Plastic Bucket Moulds cater to industries where space optimization is a critical consideration. The square shape allows for more efficient utilization of storage areas, enabling higher stacking capacities and streamlined warehouse management.

Uniform Wall Thickness for Enhanced Strength:

Maintaining uniform wall thickness is paramount in the production of Square Plastic Buckets. These molds incorporate features that ensure consistent material distribution, resulting in buckets with enhanced strength and durability, suitable for a variety of industrial applications.

Customization for Branding and Labeling:

Square Plastic Bucket Moulds offer ample surface area for branding and labeling. Manufacturers understand the importance of customization in branding, and these molds are designed to accommodate logos, labels, and other markings, providing a distinctive identity for each product.

Seamless Integration with Automated Systems:

In industries embracing automation, Square Plastic Bucket Moulds seamlessly integrate with automated molding systems. This ensures a smooth and continuous production process, with minimal manual intervention, enhancing efficiency and reducing labor costs.

The Future Landscape of Plastic Molding: Convergence of Rounds and Squares

As the plastic molding industry progresses, the convergence of Round and Square Plastic Bucket Moulds is anticipated. Manufacturers are exploring hybrid designs that incorporate the best features of both, offering unparalleled versatility to industries that require a diverse range of plastic bucket shapes.

Environmental Considerations:

In the wake of growing environmental consciousness, manufacturers of plastic bucket molds are also focusing on sustainable materials and processes. Both Round and Square Plastic Bucket Moulds are evolving to meet eco-friendly standards, ensuring that the plastic products they produce are recyclable and environmentally responsible.

Digital Integration for Precision Control:

The future envisions the integration of digital technologies for precision control in plastic molding. Smart sensors, real-time monitoring, and data analytics will enhance the efficiency of Round and Square Plastic Bucket Moulds, providing manufacturers with valuable insights into the molding process.

In conclusion, the world of plastic molding is witnessing a dynamic interplay between Round and Square Plastic Bucket Moulds, each offering unique advantages to industries with distinct storage and transport needs. As technology continues to advance, these molds will undoubtedly play a crucial role in shaping the future of plastic manufacturing, combining precision, efficiency, and sustainability in the production of high-quality plastic buckets.

中文简体

中文简体 English

English

.jpg)