Paint bucket is an important loading container for chemical solutions such as paint and paint. A good paint bucket not only requires plastics to be environmentally friendly and healthy, with low water absorption, but also has strong compression and impact resistance, and good heat resistance. Chemical. Of course, high-quality paint buckets with these advantages must be inseparable from high-quality production equipment, and paint bucket molds are particularly important.

Before introducing the paint bucket mold, first of all, let's understand the plastic paint bucket product so that we can better understand it.

Introduction of paint bucket products

1. The shape of the paint bucket

Generally, there are three types: square, round, and oval. The most common types on the market are round and square, with a capacity of 1L~35L.

2. Classification of paint buckets

There are two types of Chinese barrels and American barrels. The difference is that there are 2~3 steps and ribs at the junction of the American barrel and the lid, while the Chinese barrel does not have it, and the barrel body is smoother.

3. Types of paint buckets

1.5L Food container mold

For novices, they may think that paint buckets and paint buckets are the same product in cognition, but they are called differently. In fact, paint buckets are a general term. There are 4 categories, namely paint buckets, paint buckets, lubricating oil buckets, Engine oil barrels, the difficulty of injection molding increases in order.

4. Test of paint bucket

Generally, there are tests such as water sealing, superimposition, drop, impact, etc. For example, the drop test of the most difficult oil drum is 1.5~3 meters.

5. The problem of paint bucket recycling

If you want to reduce the manufacturing cost, you can use regrind. However, there are many kinds of recycled materials. If it is a first-class recycled material, it is basically equal to brand new material. But if it is secondary and tertiary recycling, the color is probably not white anymore. Secondly, the proportion of recycled materials depends on the requirements for the quality of paint buckets. It would be better if you buy ready-made granulation materials. If the collection bucket is crushed, it is better to be equipped with a granulation line, which will be better.

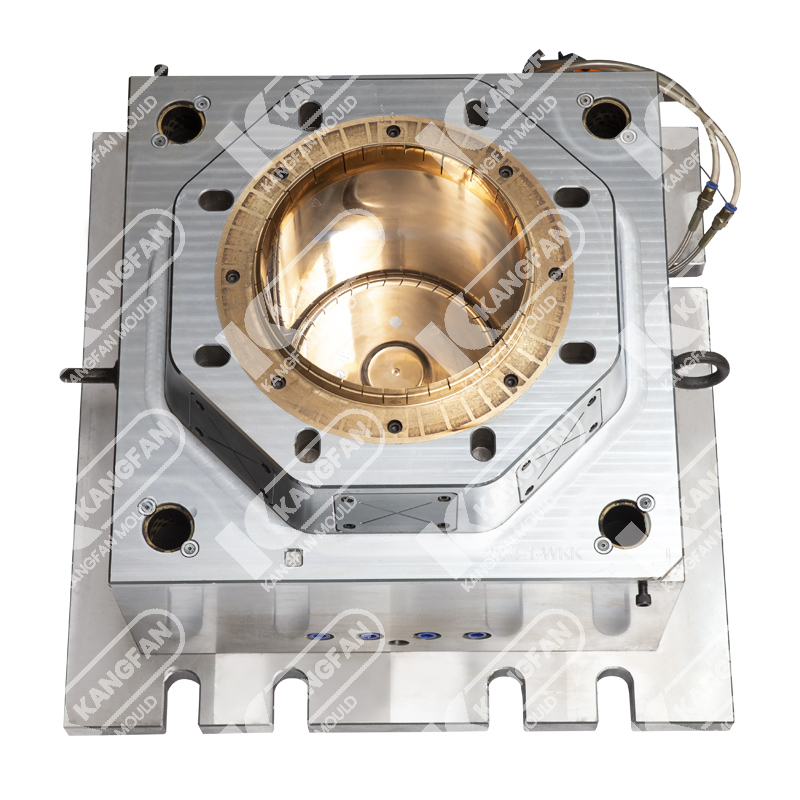

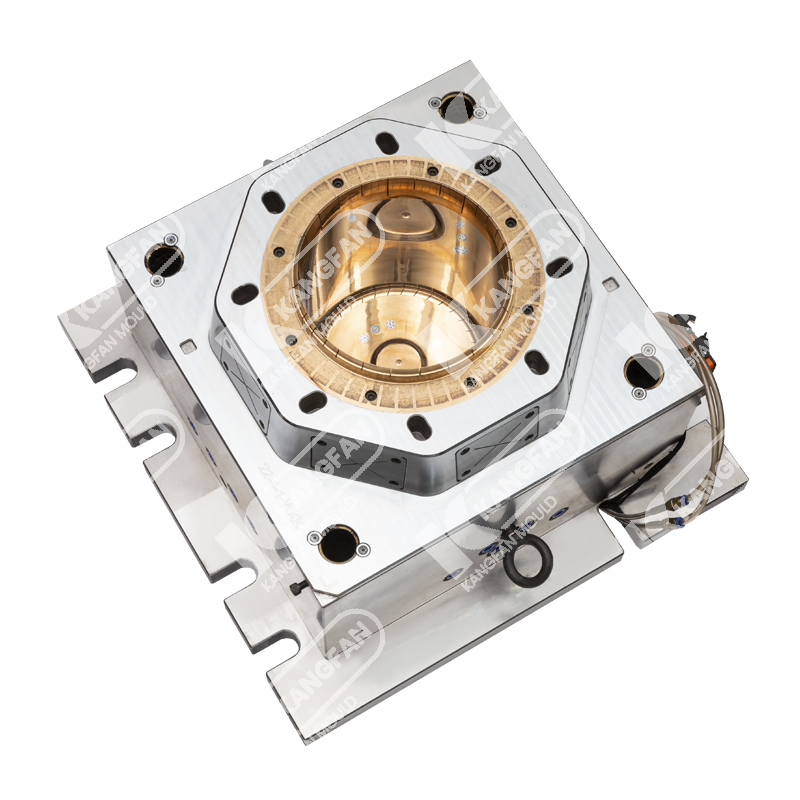

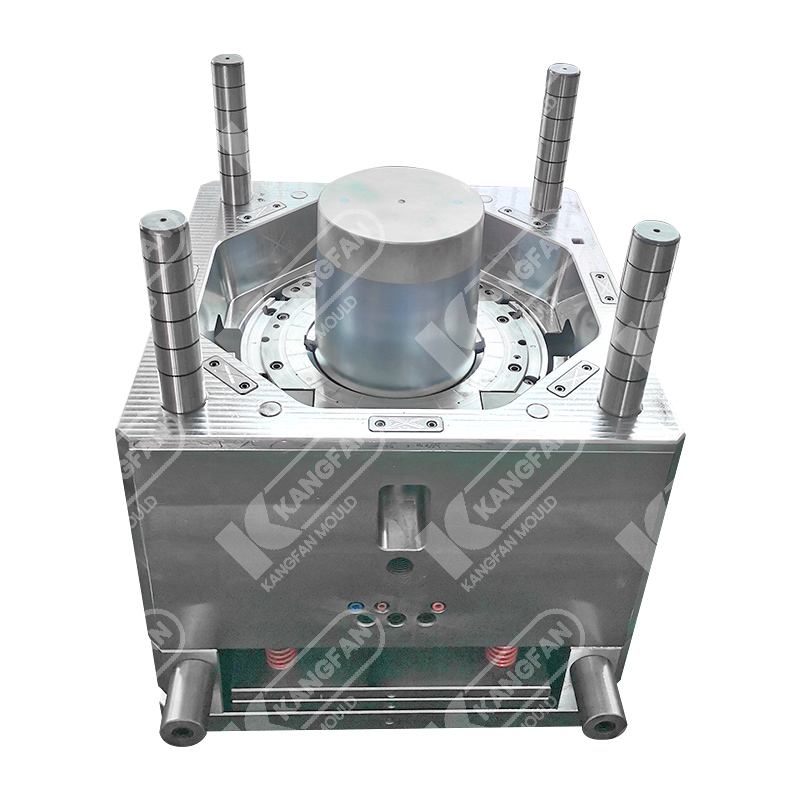

2. Introduction of Kangfan Paint Bucket Mold

1. Types of paint bucket molds

Paint bucket with slider, strong paint bucket.

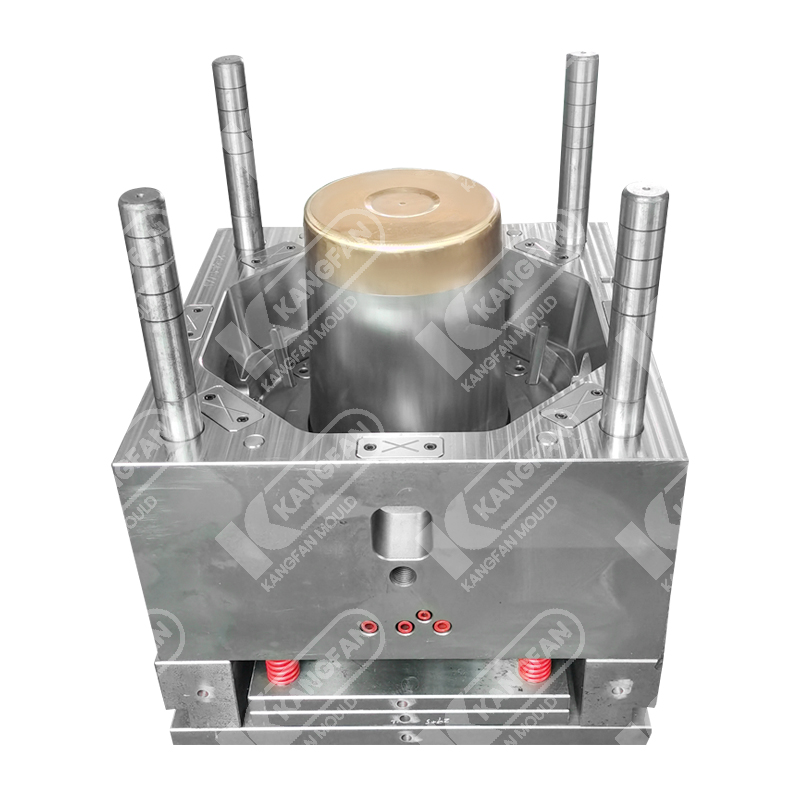

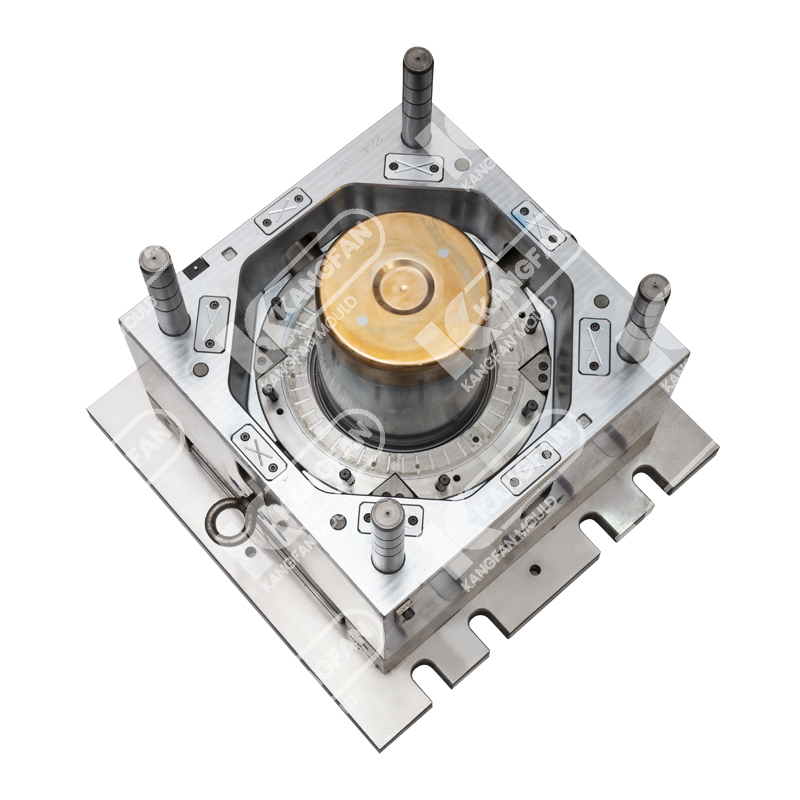

2. The ejection mechanism of the paint bucket mold

Paint bucket with slider: When the thickness of the mold is sufficient, the peripheral design is preferentially designed with a slanted roof structure.

Strong stripping mold: When the stripper plate is reversed and the stripper plate has deep ribs, it can be inlaid to solve the problem of deep rib processing. Using two ejectors, the center ejector ejects the product on the stripper plate

3. Parts design of paint bucket mold

①Cavity bottom: The bottom of the barrel needs a certain thickness, the bottom is more than 45MM, and the surrounding is fixed with screws.

②Inlaying along the mouth: To ensure the strength of the ribs along the barrel, beryllium copper can be used to facilitate cooling.

③Inlay method of slider ribs: oblique ribs and ribs with a depth of more than 12MM need to be inlaid.

4. Selection of paint bucket mold steel materials

According to the actual production requirements, high-quality steel materials such as P20, 718H, H13 and DIN1.2316 are selected, and copper beryllium is inlaid in the bottom area and the edge area.

5. Paint bucket mold injection system

There are cold runners, hot runners, hot runner needle valves, etc. Small-capacity barrels can use hot runners, and 10~15L barrels can use hot runner needle valve gates.

6. Mold exchange design

Paint bucket lids and handle inserts are interchangeable to reduce costs.

中文简体

中文简体 English

English

.jpg)