Why do many domestic and foreign customers buy plastic bucket molds and look for the Kangfan Molding brand?

Because the plastic barrel mold is one of the injection molds that Kangfan is very good at. Years of mold design and manufacturing experience have laid a solid foundation for our company. Of course, rich experience is only one of our advantages. In addition:

1. The plastic bucket molds sold to customers at home and abroad are of high quality, and the customers are well-known;

2. Others only provide molds, we provide customized services to help customers develop efficient and perfect plastic bucket mold solutions;

3. Whether it is design, materials, manufacturing, assembly, or testing, quality is paramount, never perfunctory, and build a good mold for customers with details;

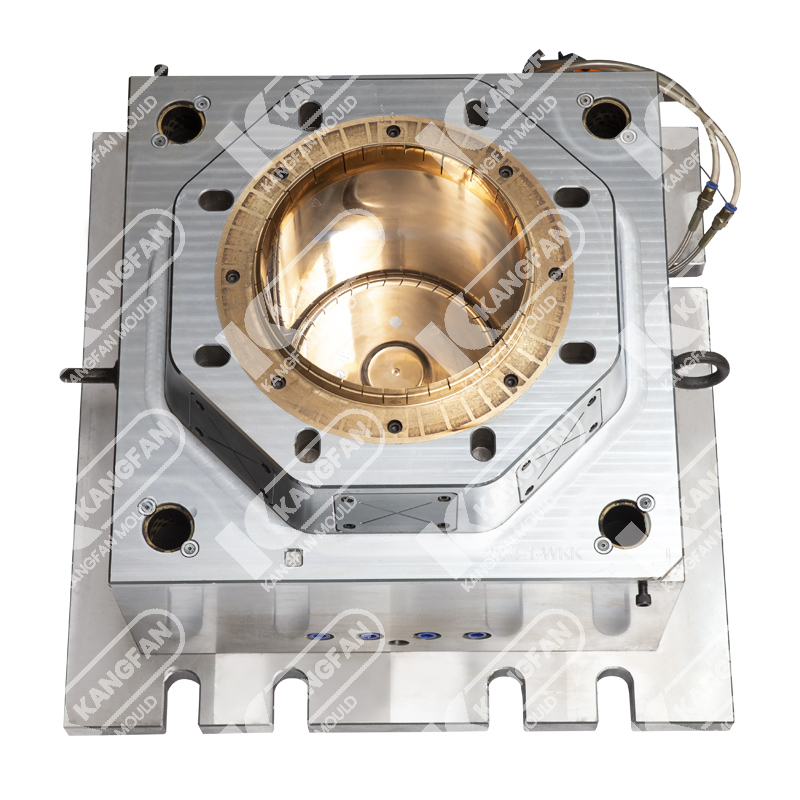

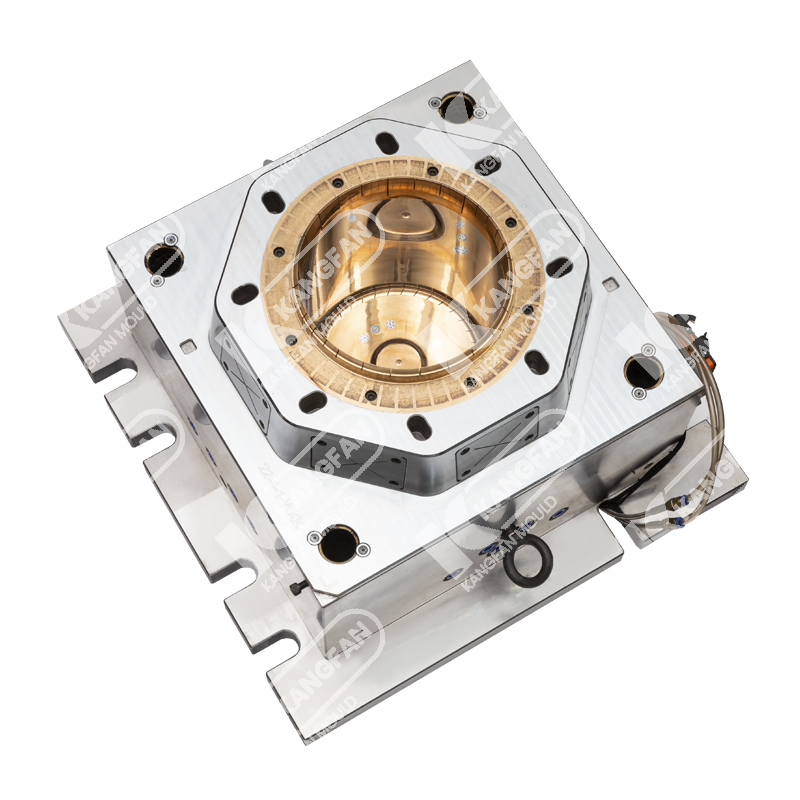

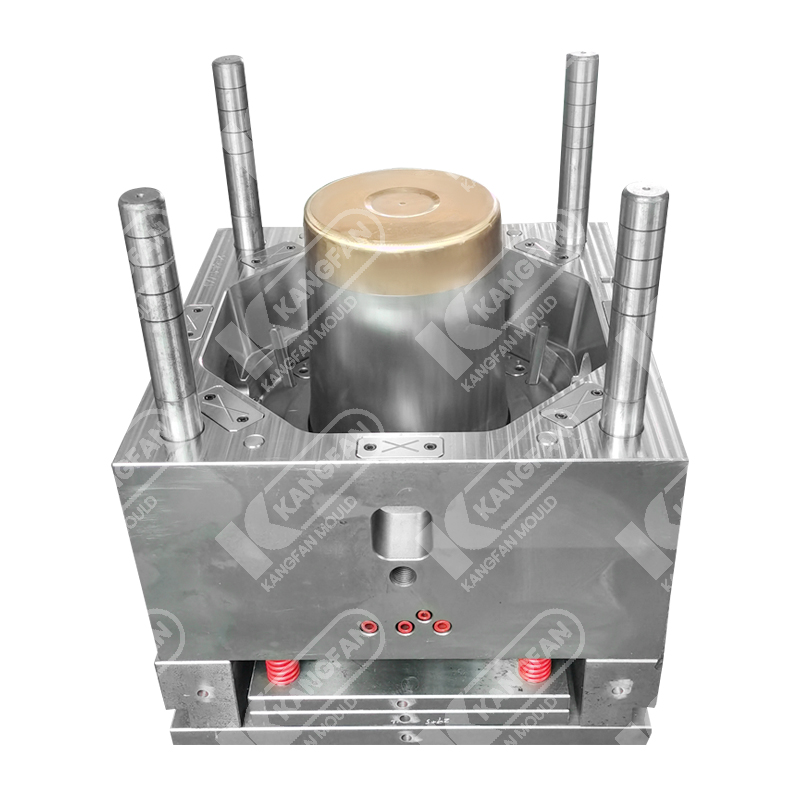

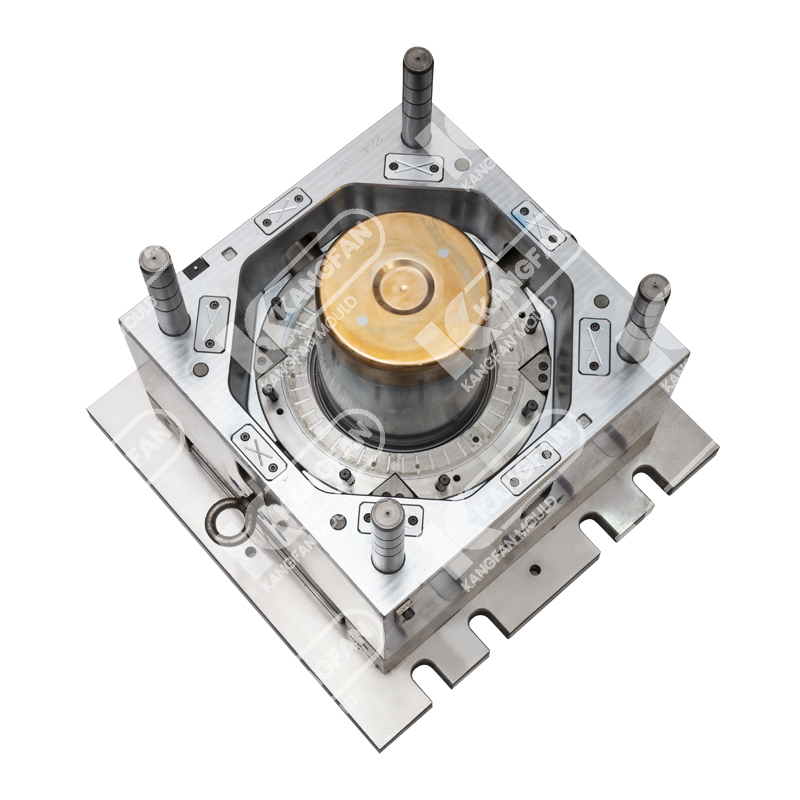

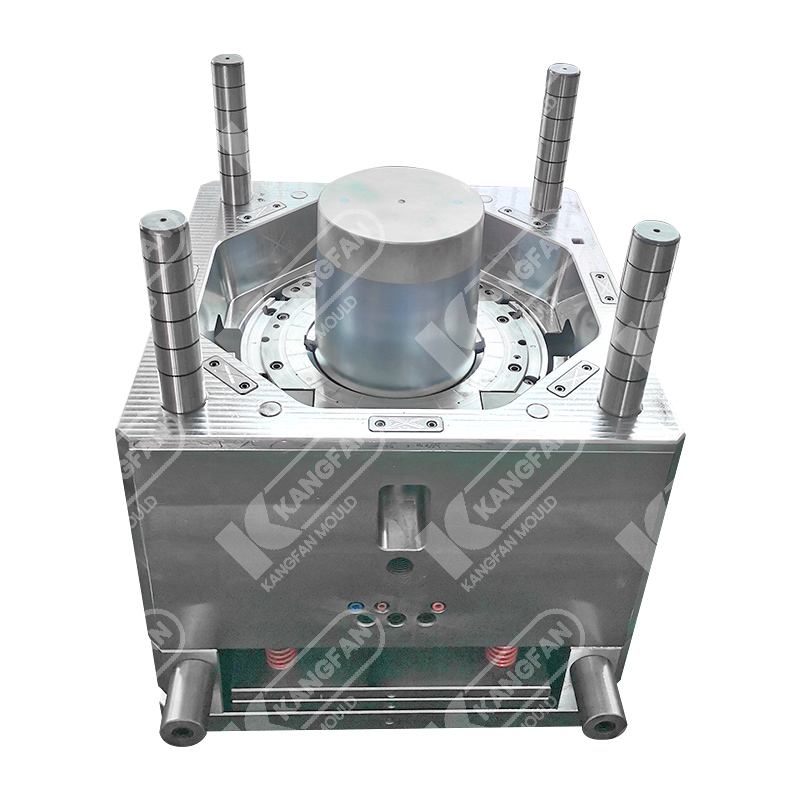

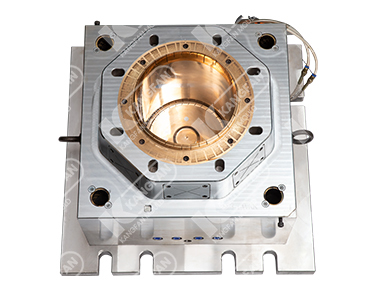

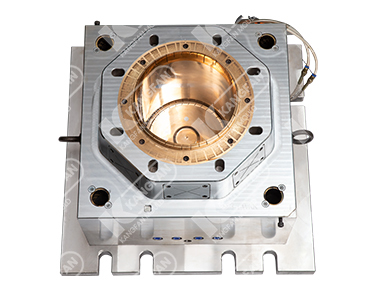

3.8L Paint bucket mould

4. Perfect after-sales service allows customers to continue to choose to cooperate with us.

Key points for making plastic bucket molds:

1. Usually, the plastic material used for plastic barrels is PP or PE, and the steel materials used for the mold can be P20, 718H, H13 and DIN1.2316;

2. The gate method used for general barrel molds is: small barrels are hot runner point gates; large barrels are large hot runner gates; extra-large ones are hot runner multiple large gates;

3. In order to reduce the cooling time, an excellent cooling water circuit is designed, and beryllium copper is embedded in the bottom area and the edge area to achieve efficient and rapid cooling cycle;

If the design is good, the accuracy of the mold cannot be guaranteed without good processing equipment. We use first-class mold processing machinery, including high-precision five-axis computer numerical control milling machine, mirror spark machine, etc. High-precision processing effectively solves the problems of mold eccentricity and sealing.

PREV:How much do you know about plastic bucket injection molds for construction industry?NEXT:How much do you know about paint bucket molds?

中文简体

中文简体 English

English

.jpg)