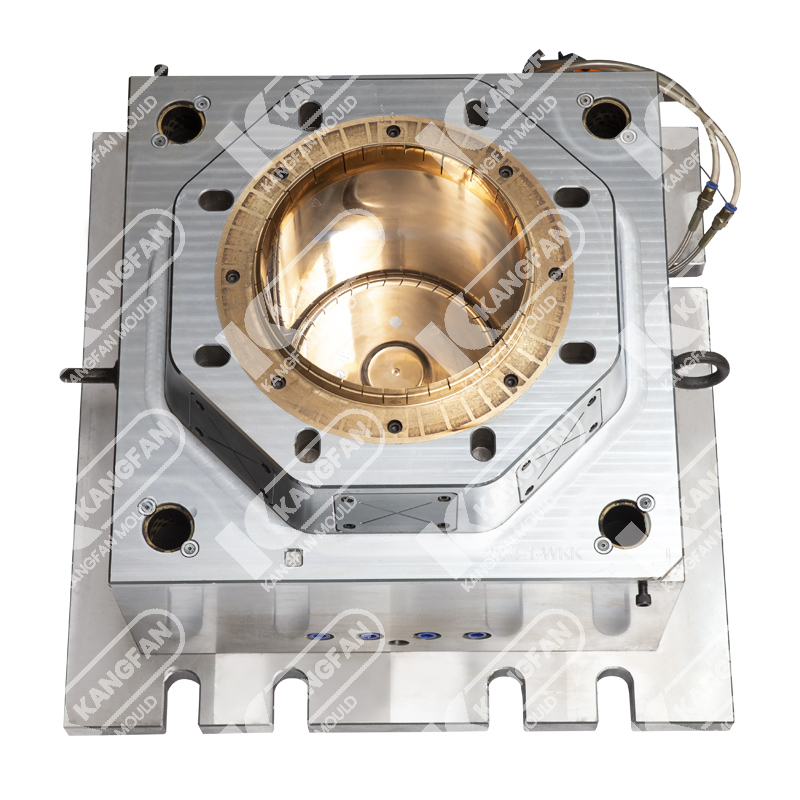

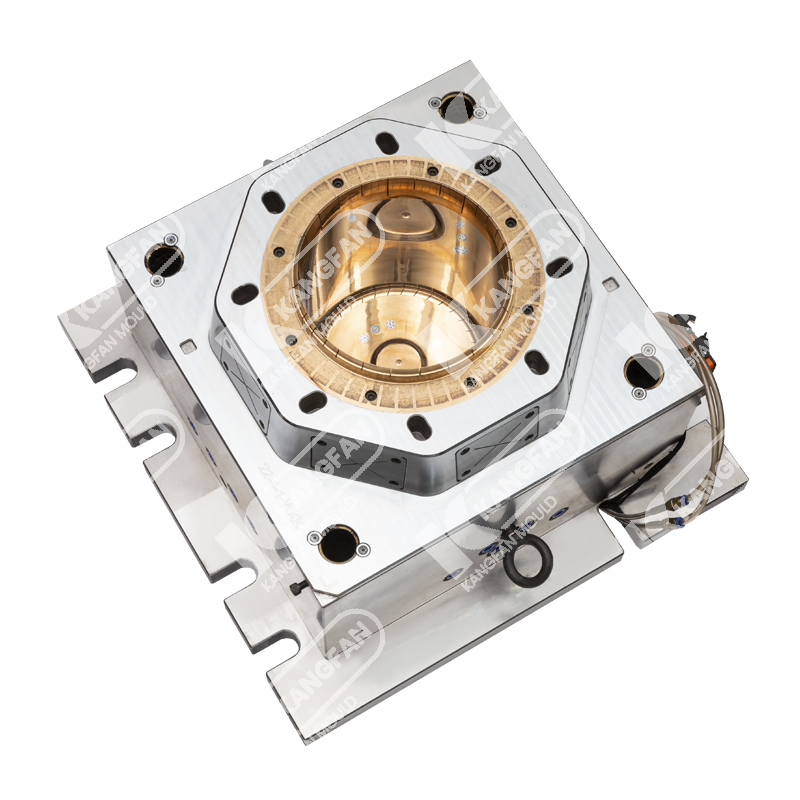

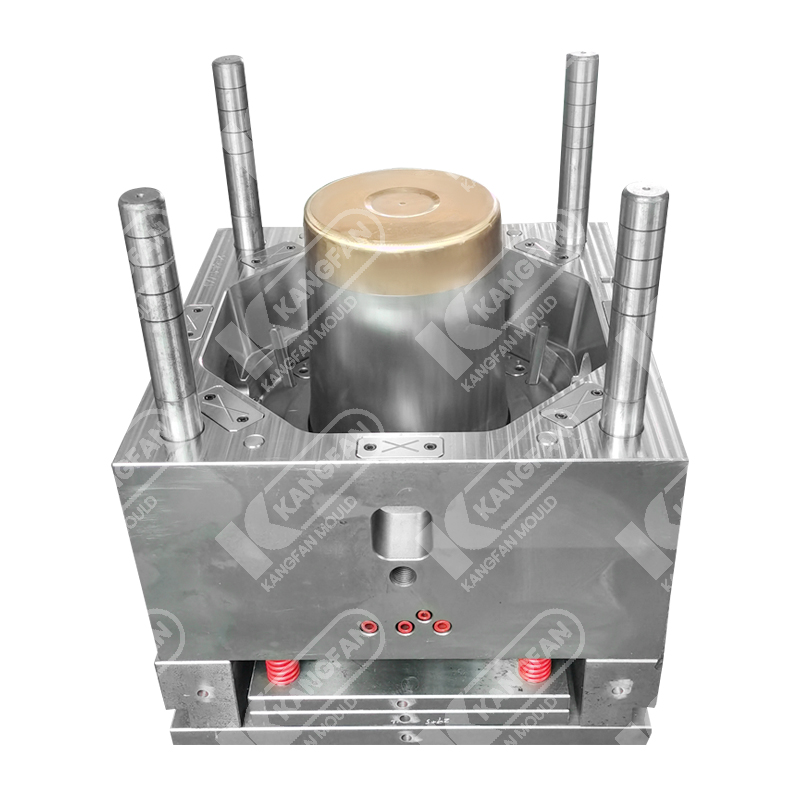

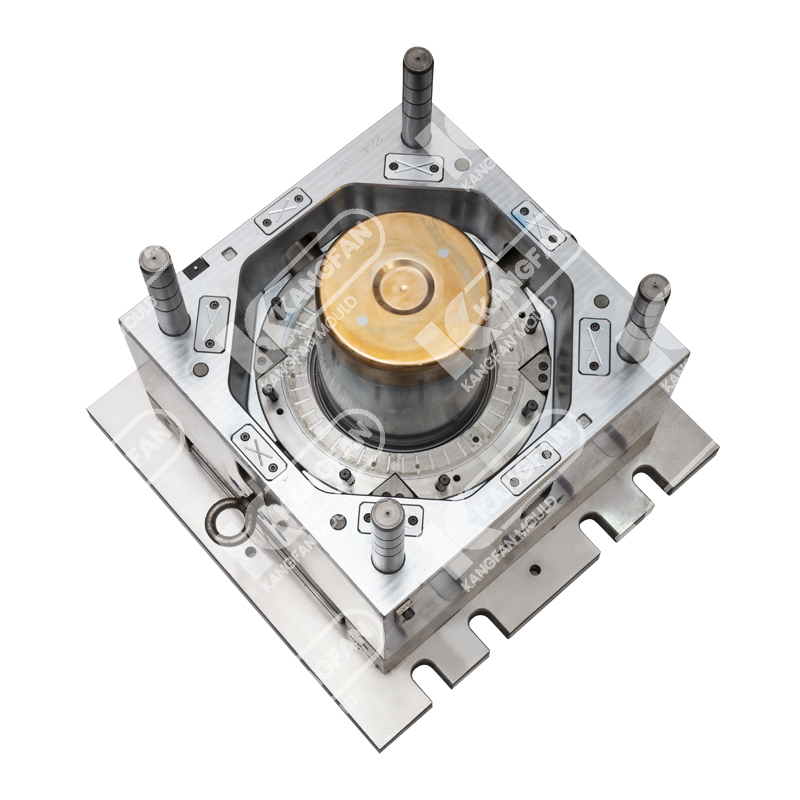

Innovating the Molded Future Unveiling Design Innovations in the Bucket Mold Factory

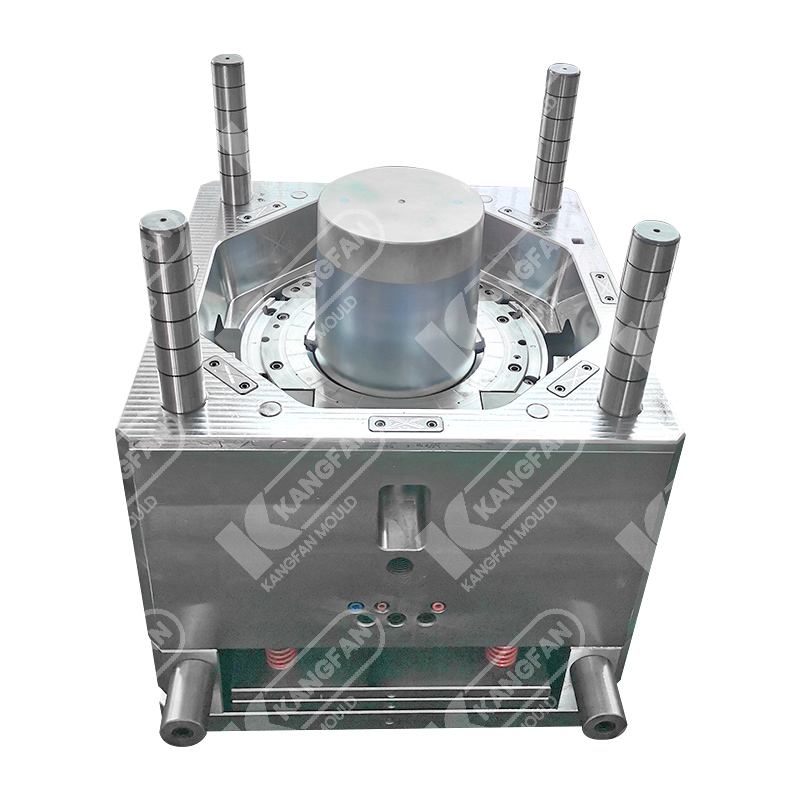

Custom Sale High-Quality OEM Bucket Mold Factory Company

In the ever-evolving landscape of molded products, the bucket mold factory stands at the forefront of innovation, continuously pushing boundaries to meet the dynamic demands of the market. This statement explores the novel design concepts and their commitment to staying ahead of market trends and adapting to the ever-changing needs of customers.

At the core of the bucket mold factory's design approach is an adaptive philosophy. The factory embraces flexibility, allowing for swift adjustments to design concepts to meet the diverse and evolving requirements of the market.

Ergonomics plays a pivotal role in bucket mold design. The factory integrates ergonomic principles to ensure that molded buckets are not only aesthetically pleasing but also user-friendly and comfortable to handle.

The factory engages in creative shape exploration. Novel and unconventional bucket shapes are explored, challenging traditional designs and offering customers fresh, innovative options that stand out in the market.

The bucket mold factory introduces customizable features for branding. This includes the incorporation of areas for logos, embossed patterns, or unique textures that allow brands to establish a distinct identity on their molded products.

Parametric design takes center stage. The factory leverages parametric design principles, enabling the creation of highly customizable molds that can be easily adapted to different sizes, volumes, and structural variations.

Sustainability is a key consideration in mold design. The bucket mold factory incorporates sustainable design practices, exploring materials and design concepts that reduce environmental impact and align with the growing demand for eco-friendly products.

Multi-cavity molds are explored for increased efficiency. The factory innovates by designing molds with multiple cavities, allowing for simultaneous production of multiple buckets, thus enhancing production throughput.

The injection molding process is optimized through smart design. The bucket mold factory introduces innovative designs that enhance the efficiency of the injection molding process, reducing cycle times and reducing material waste.

Cooling techniques are reimagined. The factory integrates advanced core and cavity cooling techniques to achieve uniform temperature distribution, resulting in faster cycle times and distortions in the molded buckets.

Advanced tooling technologies changed the design phase. The factory adopts tooling technologies that enhance precision, reduce lead times, and ensure the longevity of molds under repeated usage.

Digital twin concepts are employed in prototyping. The factory creates digital twins of molds for prototyping, allowing for a virtual testing environment that aids in refining designs before physical prototypes are produced.

AR technology is harnessed for design visualization. The bucket mold factory uses AR applications to provide customers with immersive experiences, allowing them to visualize and interact with the proposed mold designs in real-world contexts.

Real-time monitoring is facilitated by IoT integration. The factory incorporates IoT sensors into molds, enabling real-time monitoring of temperature, pressure, and other variables, leading to proactive adjustments and enhanced quality control.

Material science innovations are actively pursued. The bucket mold factory collaborates with material scientists to explore advanced materials that offer enhanced durability, resistance to wear and tear, and improved aesthetics.

Customer feedback is a catalyst for continuous learning. The bucket mold factory values customer input and uses feedback to refine and enhance design concepts, ensuring that each iteration aligns with market expectations and emerging trends.

In the realm of bucket mold design, innovation is not just a goal but a continuous journey for the bucket mold factory. Through adaptive design philosophies, sustainable practices, and the integration of technologies, these factories redefine the possibilities in molded products. As market demands evolve, the bucket mold factory anticipates trends, embraces novel concepts, and shapes a future where molded products seamlessly blend innovation, functionality, and aesthetics.

中文简体

中文简体 English

English

.jpg)