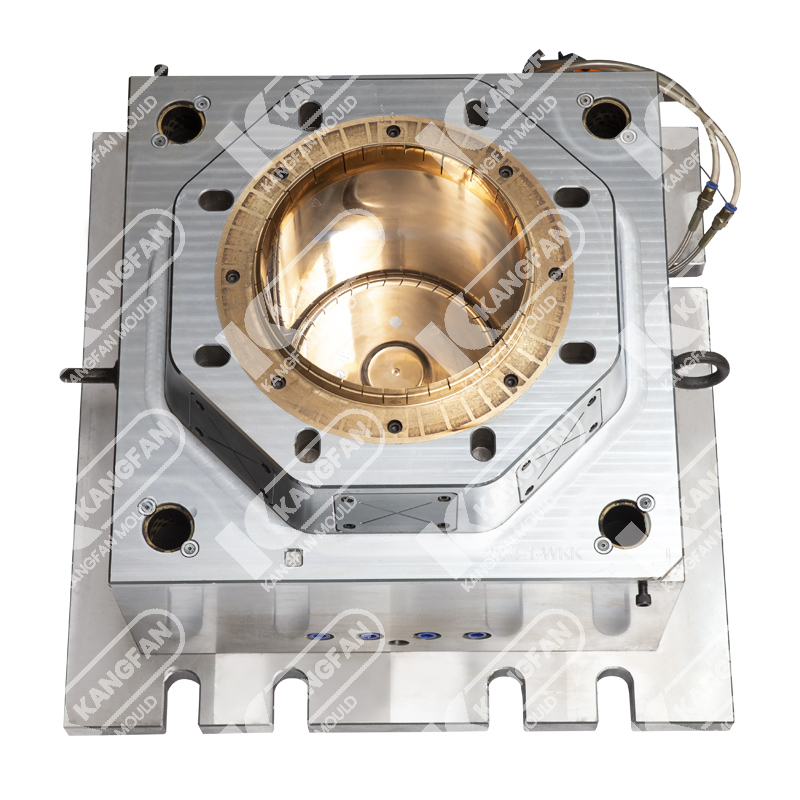

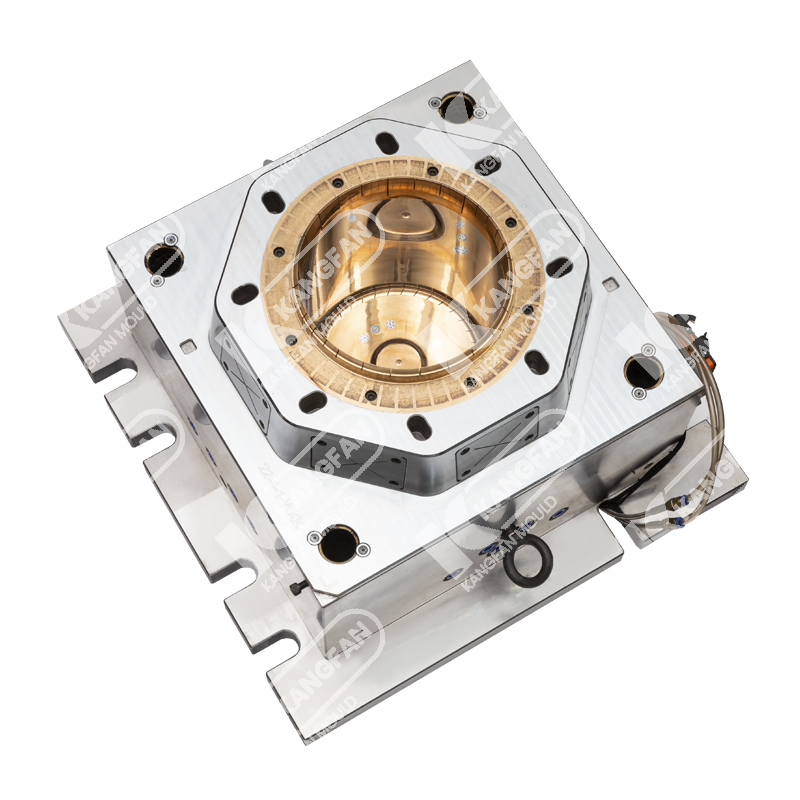

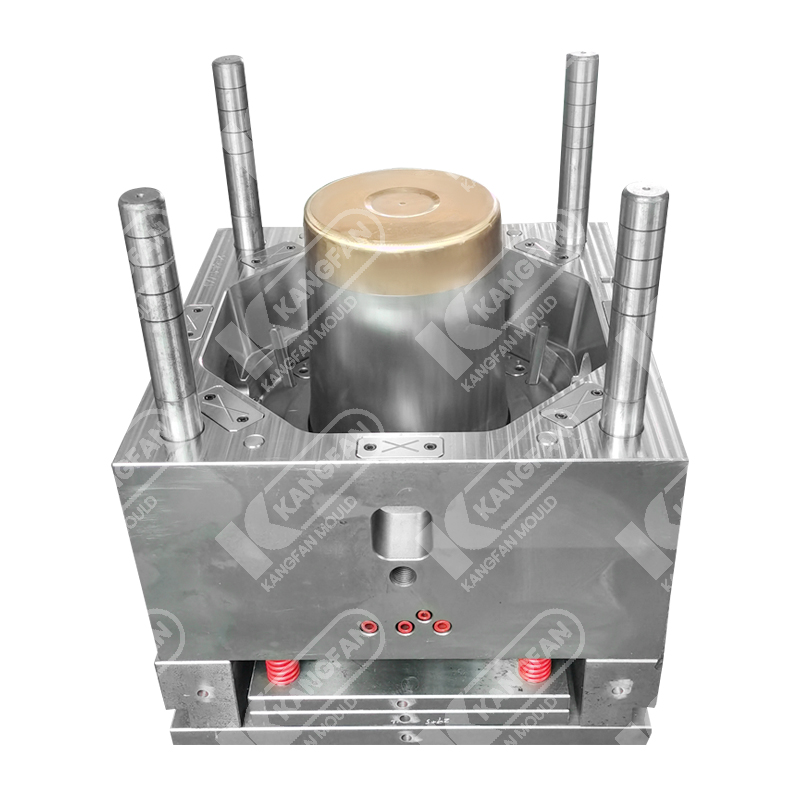

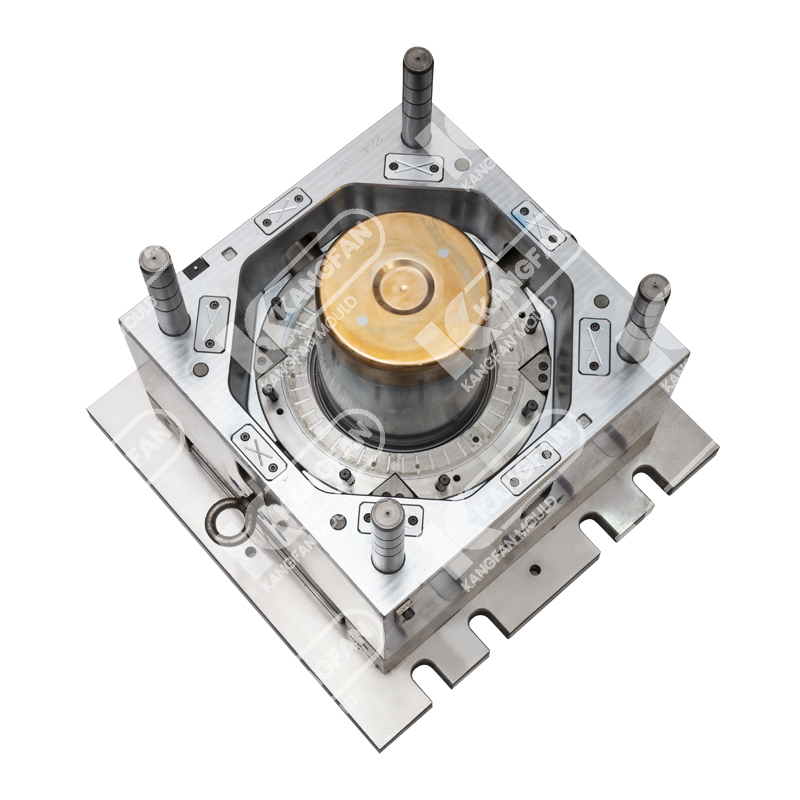

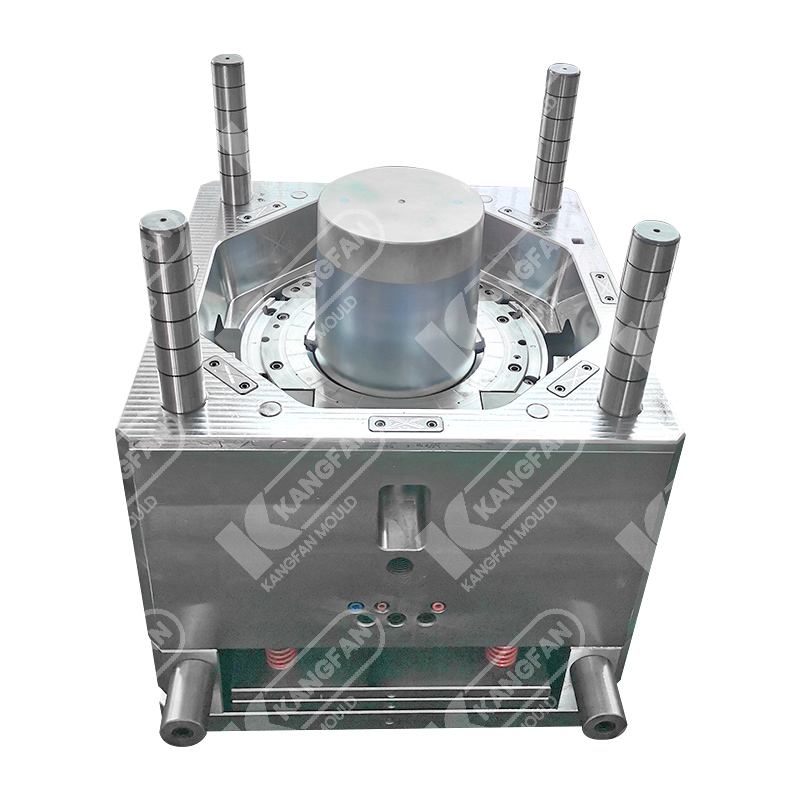

China Wholesale Custom Bucket Mold Factory Manufacturer

In the realm of molding, the versatility of a bucket mold factory extends beyond standardized production to cater to the unique and specific demands of customers. The ability to craft molds that align with diverse bucket shapes, sizes, and special requirements sets these factories apart. This statement delves into the strategies employed by the bucket mold factory to seamlessly meet and exceed customer expectations, showcasing their commitment to precision and customization.

At the heart of a bucket mold factory's ethos is a customer-centric approach. The customization journey begins with collaborative design consultations. The bucket mold factory actively engages with customers to understand their vision, preferences, and any special requirements for the bucket mold.

CAD plays a pivotal role in translating customer concepts into tangible designs. The factory utilizes advanced CAD software to create precise and detailed molds that mirror the specific shapes and dimensions desired by the customer.

Before full-scale production, the bucket mold factory often creates prototypes for customer approval. This iterative process allows customers to visualize and approve the design before committing to mass production.

Material flexibility is key to meeting customization demands. The bucket mold factory offers a range of materials, each chosen for its specific properties, enabling customers to select the material that suits their requirements for durability, temperature resistance, and other factors.

To accommodate varying shapes and sizes, the bucket mold factory designs molds with adjustable components. This adaptability allows for swift modifications to cater to specific customer requests without the need for extensive redesign.

In-house tooling expertise is a distinctive feature. The factory's skilled tooling experts possess the knowledge and craftsmanship to adapt molds to unique shapes, ensuring precision and maintaining the integrity of the final product.

Responsive customer support is a cornerstone of customization. Bucket mold factories establish open lines of communication, ensuring that customers can convey any adjustments or special requirements throughout the production process.

Quality assurance is not compromised in customization. Bucket mold factories implement stringent quality control measures to ensure that customized molds meet industry standards and surpass customer expectations.

Streamlined prototyping techniques expedite the customization process. The factory employs efficient prototyping methods that allow for quick adjustments based on customer feedback, reducing lead times for tailored mold production.

Collaboration extends to the customer's design team. The bucket mold factory actively works alongside customer designers, leveraging collective expertise to refine and perfect the mold design according to specific bucket requirements.

The iterative design review process is integral. Customers participate in design reviews, providing feedback at various stages to ensure that the evolving mold aligns precisely with their expectations and requirements.

Bucket mold factories ensure scalability for bulk custom orders. The production processes are designed to seamlessly transition from prototyping to mass production while maintaining the integrity of the customized design.

The commitment to customization extends beyond the sale. Bucket mold factories provide post-sale support and offer modifications if required, demonstrating an ongoing dedication to customer satisfaction.

Customer feedback is a catalyst for continuous improvement. Bucket mold factories actively seek customer input, using feedback to refine processes, enhance customization capabilities, and stay ahead of evolving customer demands.

In the dynamic landscape of molding, a bucket mold factory's ability to meet customer demands for specific shapes, sizes, and special requirements is a testament to its dedication to precision and customization. Through collaborative design consultations, advanced technologies, and a commitment to quality, these factories seamlessly weave together customer visions with manufacturing expertise, resulting in molds that not only meet but exceed customer expectations. As the industry evolves, the bucket mold factory stands poised to continue its journey of customization, embracing innovation and customer collaboration to shape the future of molded products.

中文简体

中文简体 English

English

.jpg)