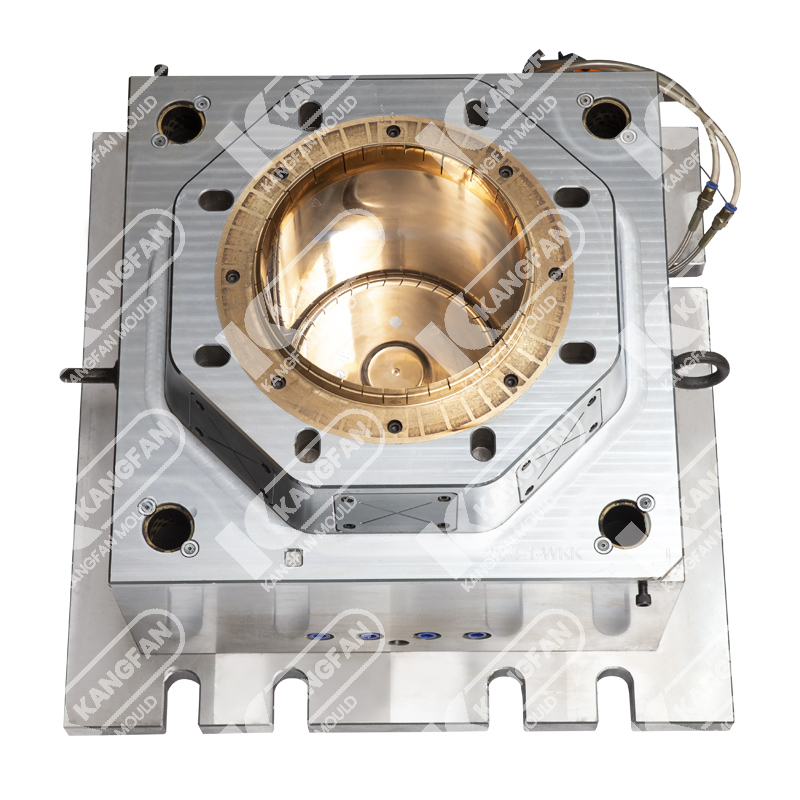

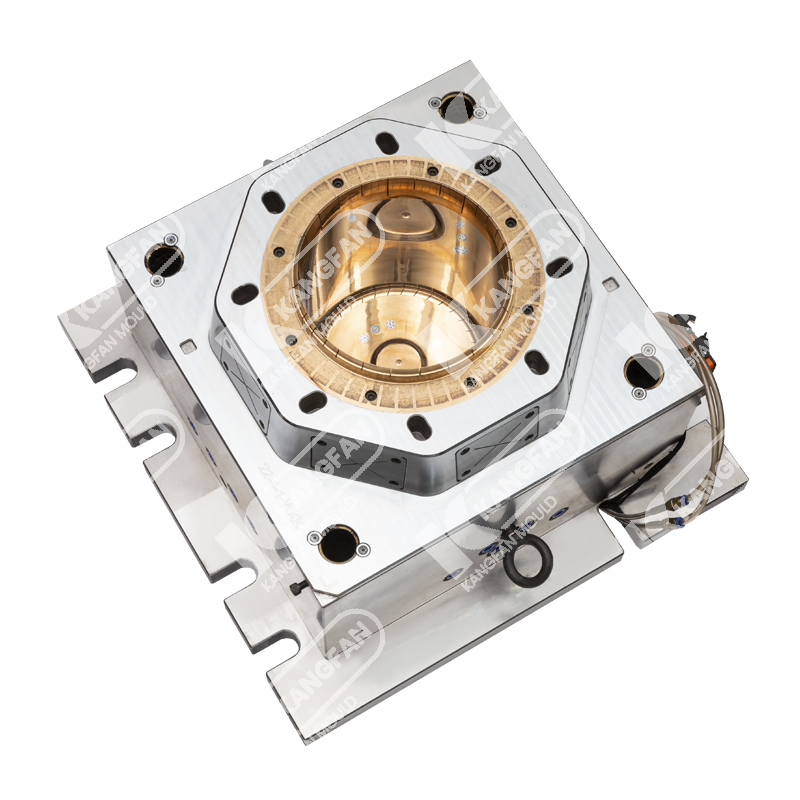

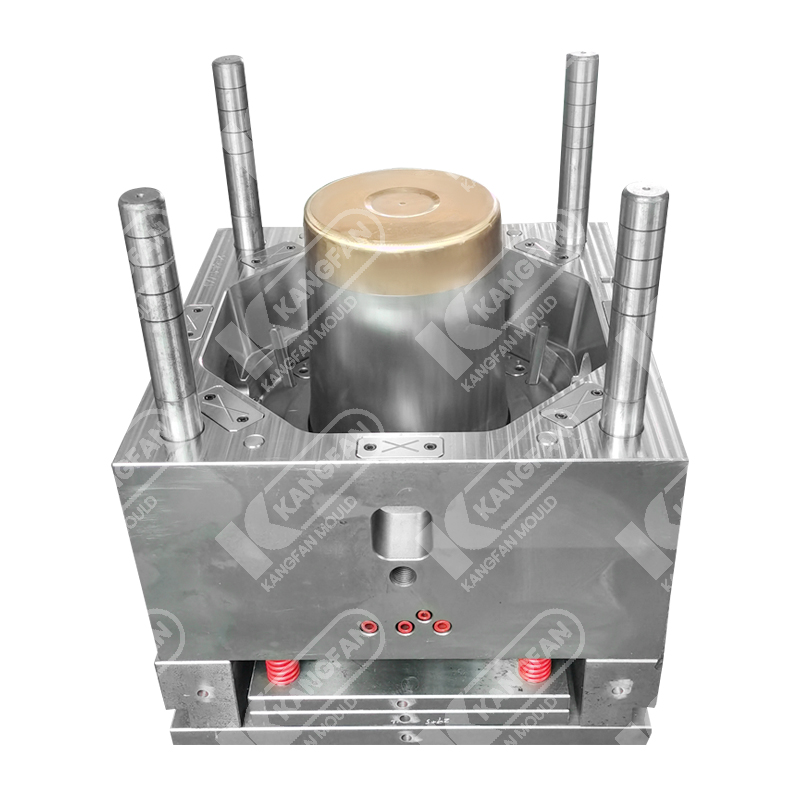

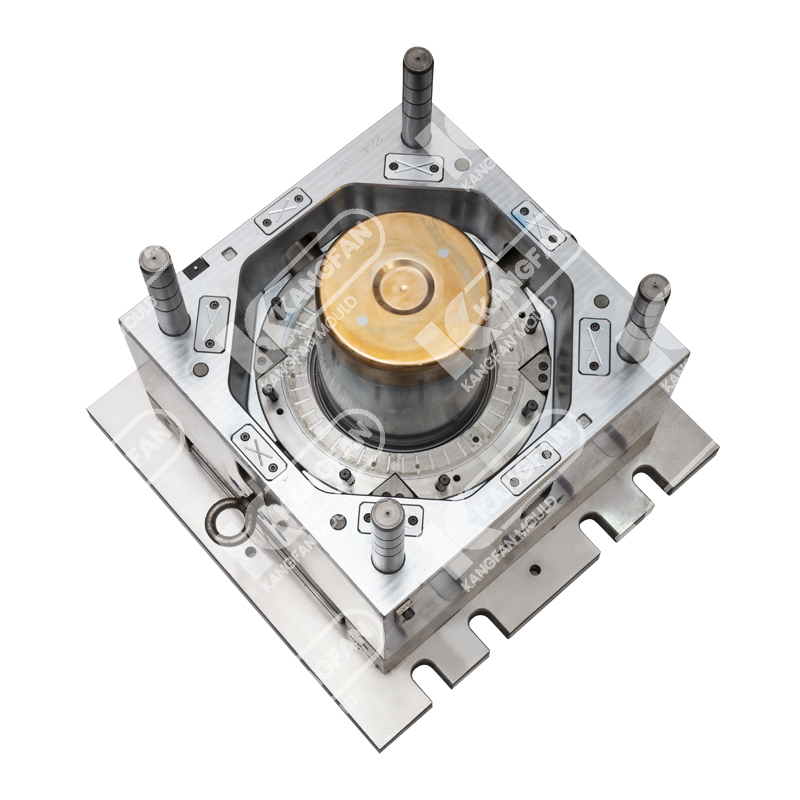

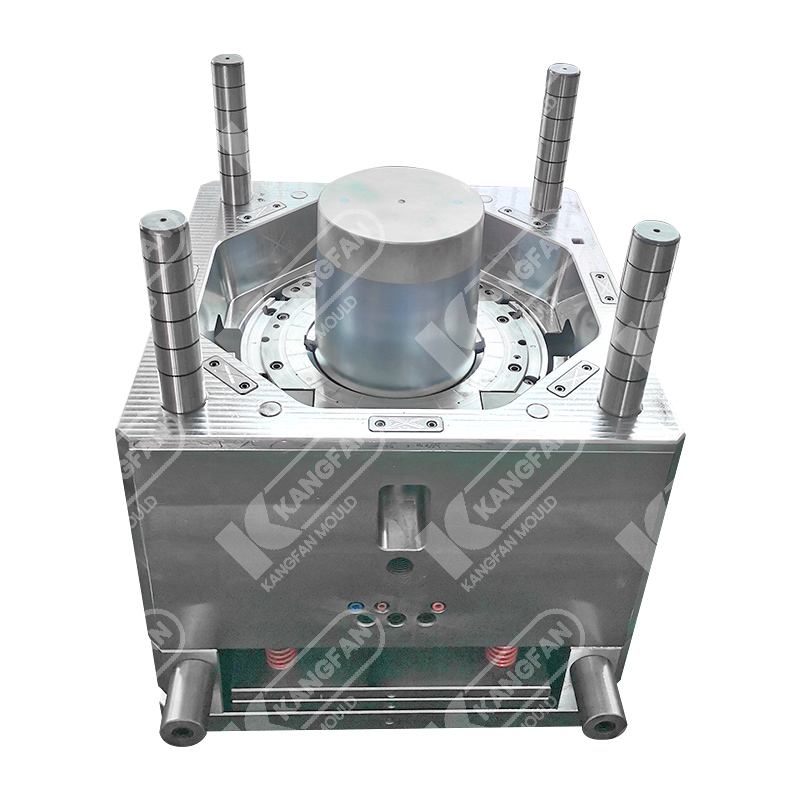

Innovative Shaping Bucket Mold Factory Technology To Improve Quality And Efficiency

High-Quality Design Custom OEM Bucket Mold Factory in China

In the realm of bucket mold manufacturing, the advent of advanced technologies has ushered in a new era of precision, efficiency, and quality. The bucket mold factory, committed to staying at the forefront of innovation, strategically integrates technologies into its production processes. This statement delves into the sophisticated technologies employed by bucket mold factories, exploring how these advancements elevate the quality of molds and streamline production for efficiency.

At the core of bucket mold design is Computer-Aided Design (CAD). The factory utilizes advanced CAD software to create intricate and precise blueprints, ensuring accuracy in every detail of the mold's structure.

CNC machining plays a pivotal role in transforming digital designs into physical molds. The bucket mold factory leverages CNC technology for precise and automated machining, resulting in molds with consistent quality and accuracy.

The choice of materials is paramount. Bucket mold factories explore high-performance materials and alloys that exhibit superior durability, heat resistance, and longevity, enhancing the overall quality and lifespan of the molds.

Innovation is fostered through 3D printing technology. The bucket mold factory employs 3D printing for creating prototypes, allowing for rapid prototyping and iterative design improvements before finalizing the production mold.

Simulating mold flow is critical for optimization. Advanced technologies enable bucket mold factories to conduct mold flow analyses, predicting and optimizing the flow of molten material during the injection molding process for enhanced efficiency.

The injection molding process is a key focus. Bucket mold factories invest in precision injection molding machines equipped with advanced controls, ensuring consistent molding parameters and reducing the risk of defects.

IoT integration enhances real-time monitoring. Smart sensors on molds and machines allow the bucket mold factory to collect data on temperature, pressure, and other variables, facilitating proactive adjustments and quality control.

Ejecting molded parts efficiently is streamlined through automated ejection systems. The bucket mold factory adopts advanced ejection mechanisms that enhance the speed and precision of part removal from the mold.

Cooling is a critical phase in molding. Bucket mold factories deploy innovative cooling systems, such as conformal cooling, to ensure uniform temperature distribution, reducing cycle times and reducing warping.

AR technology aids in inspection and maintenance tasks. The bucket mold factory technicians use AR applications to visualize mold designs, identify potential issues, and streamline the maintenance process for prolonged mold life.

Automation extends to post-production processes. Bucket mold factories incorporate robotics for efficient handling, packaging, and stacking of molded products, reducing manual labor and enhancing overall production efficiency.

Predictive maintenance is empowered by data analytics. By analyzing machine and mold performance data, the bucket mold factory can predict potential maintenance needs, reducing downtime and ensuring continuous production.

Sustainability is a consideration. Bucket mold factories embrace energy-efficient production practices, utilizing technologies that reduce energy consumption while maintaining high productivity levels.

Virtual Reality (VR) is employed for training purposes. The bucket mold factory workers undergo immersive VR training sessions to familiarize themselves with the molding processes and enhance skills and errors.

The journey of innovation is ongoing. Bucket mold factories invest in continuous R&D, staying abreast of emerging technologies to further enhance the precision, quality, and efficiency of their mold production processes.

The bucket mold factory, driven by a commitment to excellence, has harnessed the power of advanced technologies to redefine the standards of mold manufacturing. Through a seamless integration of CAD, CNC machining, IoT, AR, and other cutting-edge technologies, these factories not only ensure the production of high-quality molds but also pave the way for efficient, sustainable, and forward-looking molding processes. As the industry continues to evolve, the bucket mold factory stands as a testament to the transformative impact of technology on precision engineering and manufacturing.

中文简体

中文简体 English

English

.jpg)