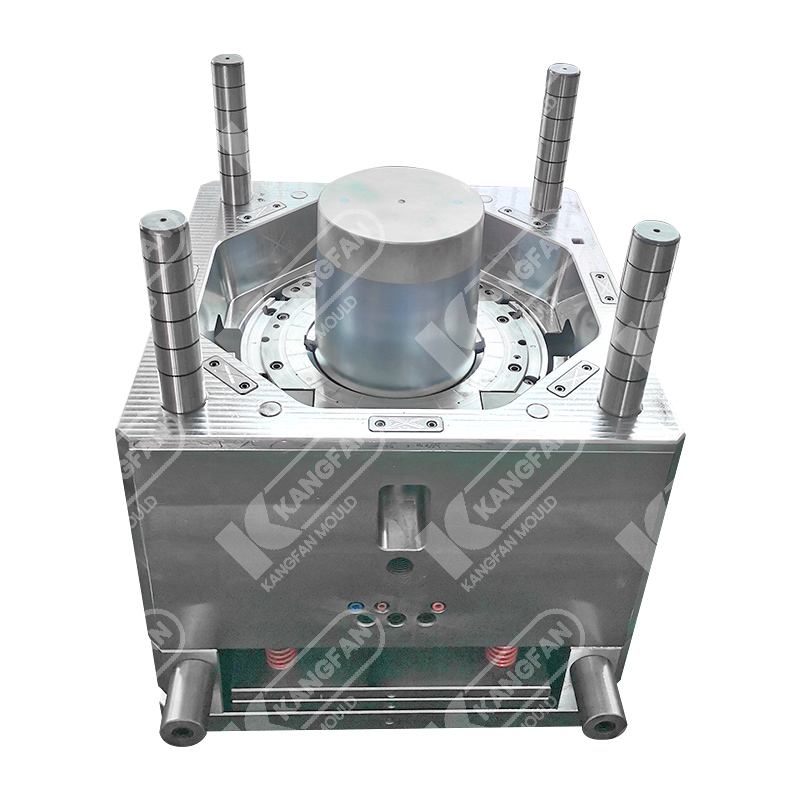

The world of manufacturing has witnessed numerous technological advancements over the years, one of which is the Paint Bucket Mould. This innovative tool has transformed the traditional process of creating paint buckets, fostering efficiency, precision, and enough design capabilities. We will delve into the captivating journey of the Paint Bucket Mould, unraveling its impact on the industry and how it has revolutionized the manufacturing landscape.

1. The Genesis of Paint Bucket Mould

The genesis of the Paint Bucket Mould can be traced back to the quest for improving manufacturing processes. Developed through a collaborative effort of designers, engineers, and material experts, this mold emerged as a game-changer in the industry. Its primary aim was to streamline the production of paint buckets, ensuring consistency in quality, design, and durability.

2. Unleashing Design Possibilities

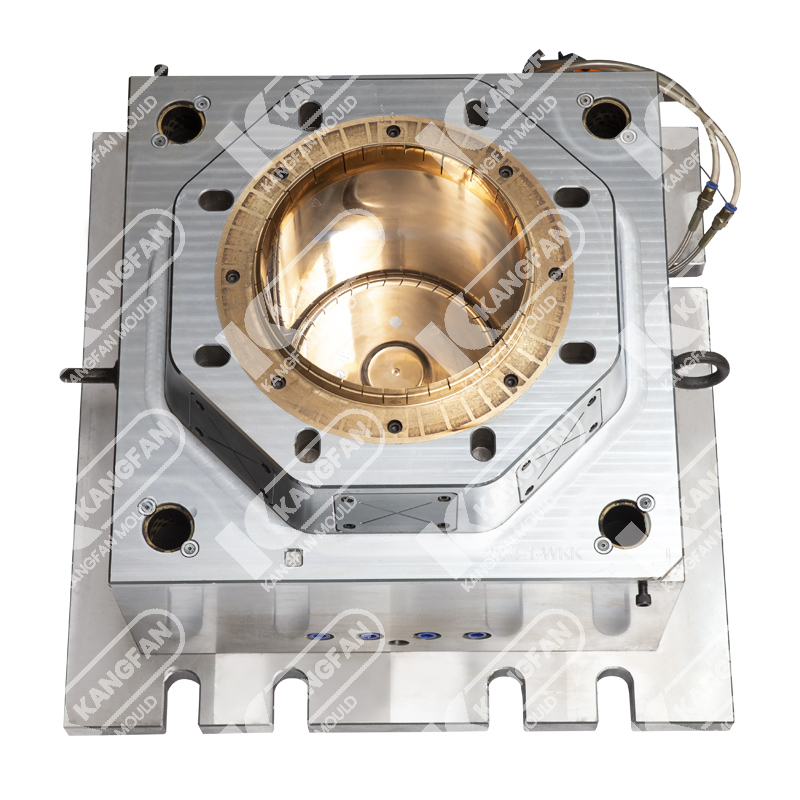

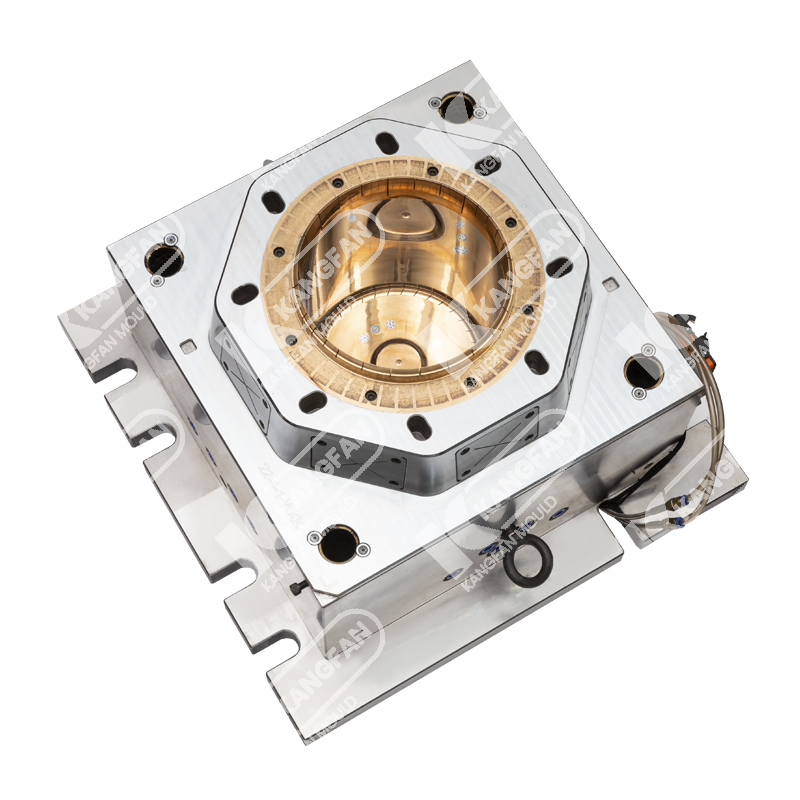

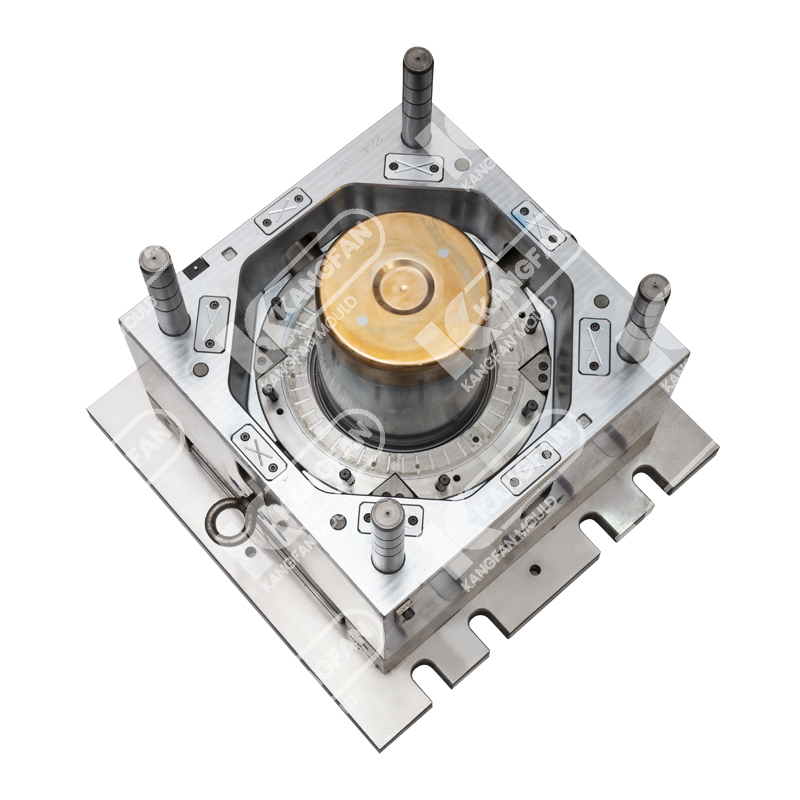

The advent of the Paint Bucket Mould shattered the constraints of manufacturing limitations. With this advanced tool, manufacturers now have the ability to create paint buckets with intricate shapes, patterns, and textures. The flexibility and precision offered by the mold allow for unlimited design possibilities that were previously unimaginable.

3. Enhanced Durability and Functionality

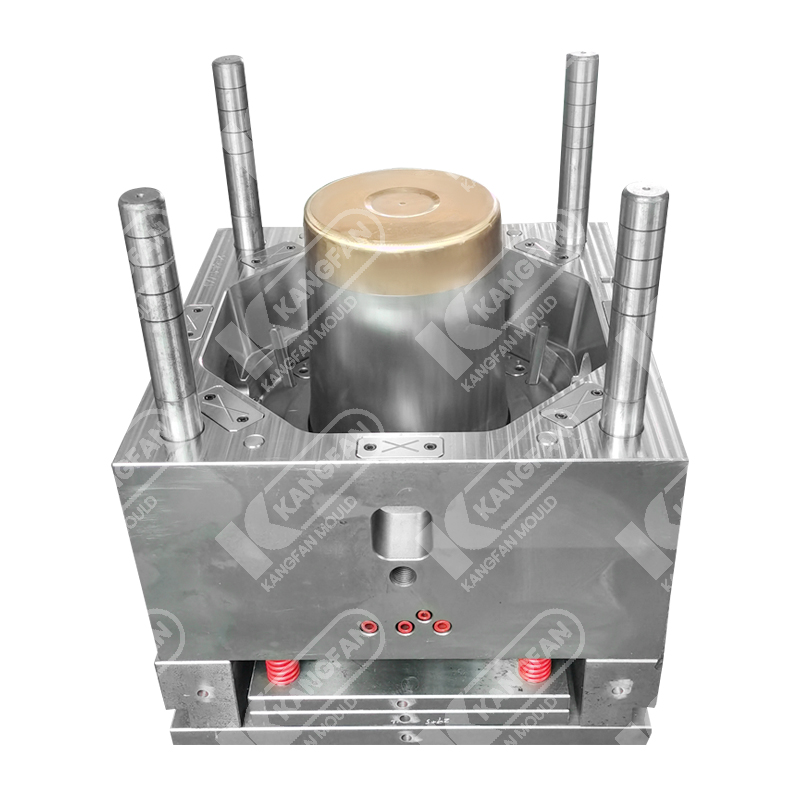

Paint Bucket Mould has revolutionized the industry by significantly enhancing the durability and functionality of paint buckets. The molds are engineered using high-quality materials that ensure longevity, resistance to temperature variations, and the ability to withstand extensive wear and tear. As a result, businesses can produce paint buckets that can endure tough conditions and maintain their integrity over time.

4. Increased Production Efficiency

Gone are the days when the production of paint buckets used to be a time-consuming and labor-intensive process. The advent of the Paint Bucket Mould has ushered in a new era of efficiency. The precision and speed provided by the mold enable manufacturers to produce a larger volume of paint buckets within a shorter timeframe, meeting market demands effectively.

5. Quality Assurance and Cost Reduction

Paint Bucket Mould ensures good quality standards for every product. Its consistent design eliminates variations, deviations, and defects, reducing the need for rework and rejection. This quality assurance not only saves costs but also reduces the environmental impact of manufacturing, making it a sustainable choice.

6. Customization for Brand Recognition

Modern businesses thrive on brand recognition, and the Paint Bucket Mould plays a pivotal role in achieving it. Tailoring paint buckets to match brand aesthetics, colors, and logos allows companies to establish a distinct identity. This customization possibility serves as a powerful marketing tool, enabling businesses to stand out in a crowded marketplace.

7. Expanding Horizons: Applications Beyond Paint Buckets

While the Paint Bucket Mould is predominantly associated with the production of paint containers, its versatility extends to various other industries. The mold is now utilized in the manufacturing of household cleaning chemical containers, industrial storage bins, and even parts for automotive applications. Its ability to adapt to diverse product designs speaks volumes about its transformative potential across multiple sectors.

The Paint Bucket Mould has revolutionized the manufacturing industry, elevating the creation of paint buckets to unprecedented levels. With its ability to unlock innovative designs, ensure durability, and enhance efficiency, this mold has become an important tool for manufacturers worldwide. As the industry continues to evolve, the Paint Bucket Mould will undoubtedly play a pivotal role in shaping the future of manufacturing, unlocking opportunities for novel applications and infinite possibilities.

PREV:The Versatile World Of Machine Plastic InjectionNEXT:The Power Of Custom Assembly Mold: Revolutionizing Manufacturing Efficiency

中文简体

中文简体 English

English

.jpg)