In the realm of manufacturing, few processes can match the efficiency, consistency, and versatility of Machine Plastic Injection. This technology has revolutionized the production of plastic parts across various industries, from automotive and medical to consumer goods and electronics. At its core, Machine Plastic Injection is a precision process that involves the injection of molten plastic into molds to create complex shapes and components.

The foundation of Machine Plastic Injection lies in its ability to accurately and rapidly produce large volumes of identical parts. This process begins with the selection of appropriate plastic materials, which are then fed into a heated barrel of an injection molding machine. The plastic is melted and mixed inside the barrel before it is injected under high pressure into a pre-designed mold cavity. Once cooled and solidified, the mold opens, and the finished part is ejected, ready for further processing or assembly.

One of the primary advantages of Machine Plastic Injection is its capacity for mass production. Unlike manual molding techniques, injection molding allows for the creation of thousands of parts with little variance in dimensions and quality. This makes it an ideal choice for mass manufacturing, where consistent product quality is important. Additionally, the speed of the injection molding cycle is unparalleled, contributing to increased productivity and lowered costs.

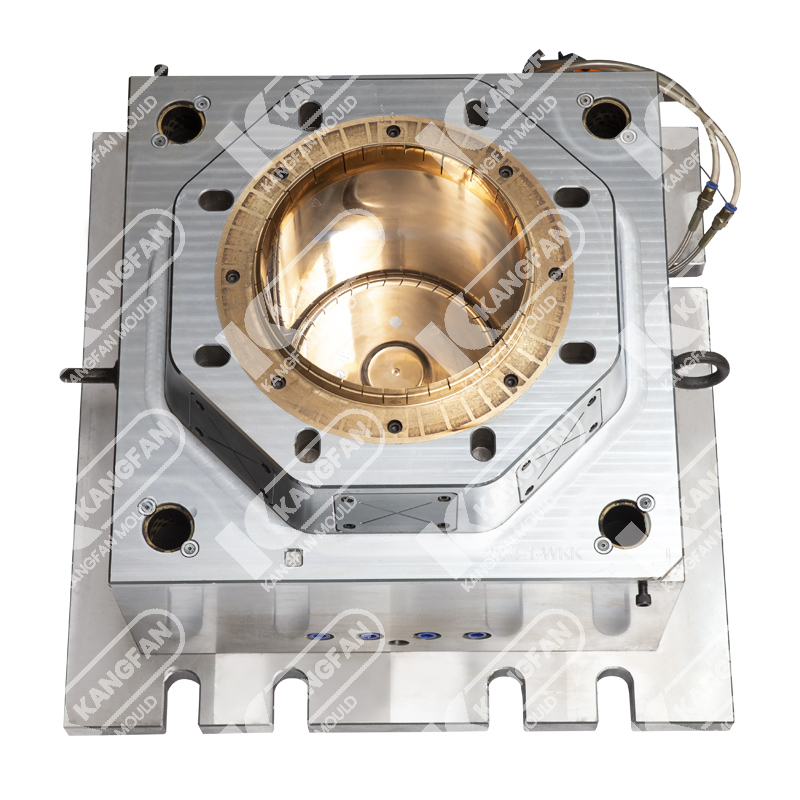

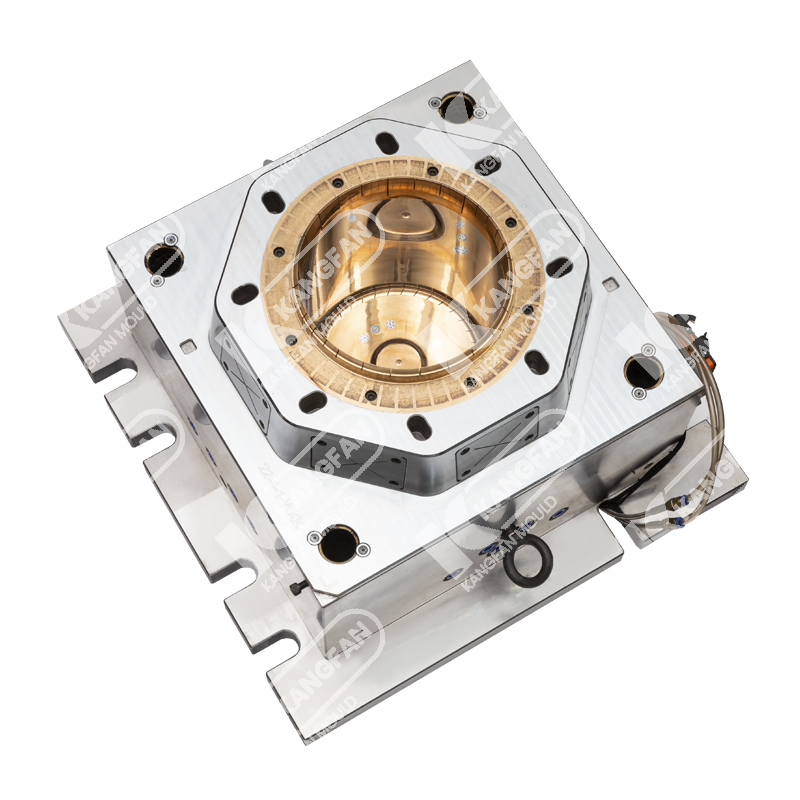

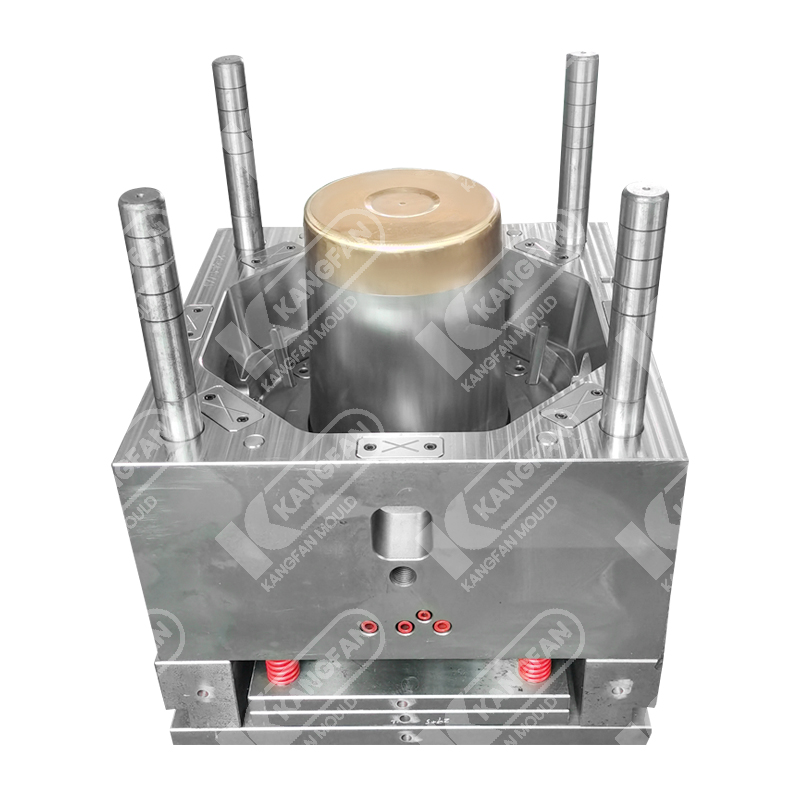

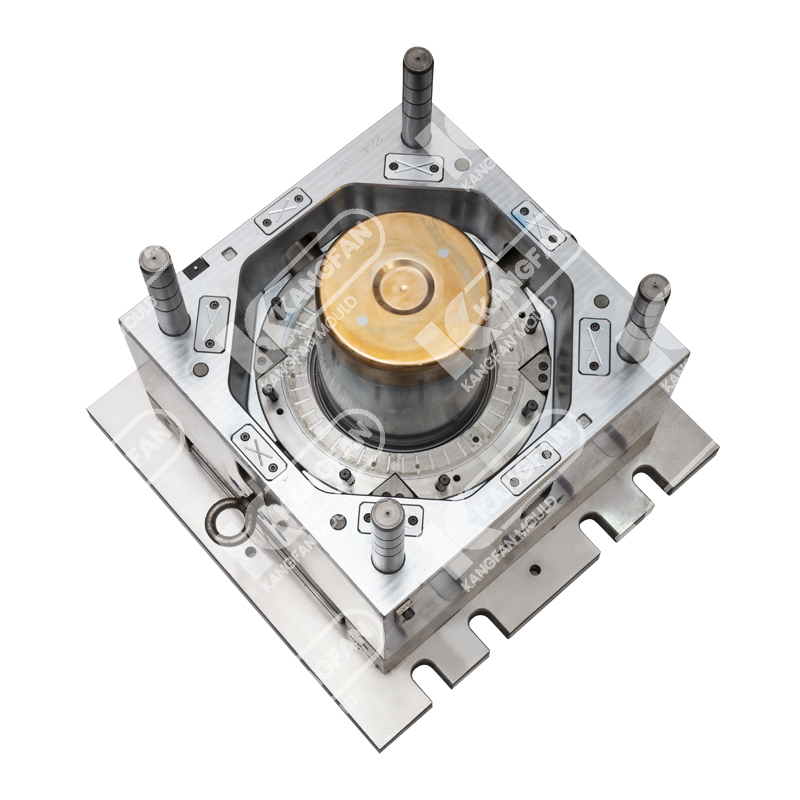

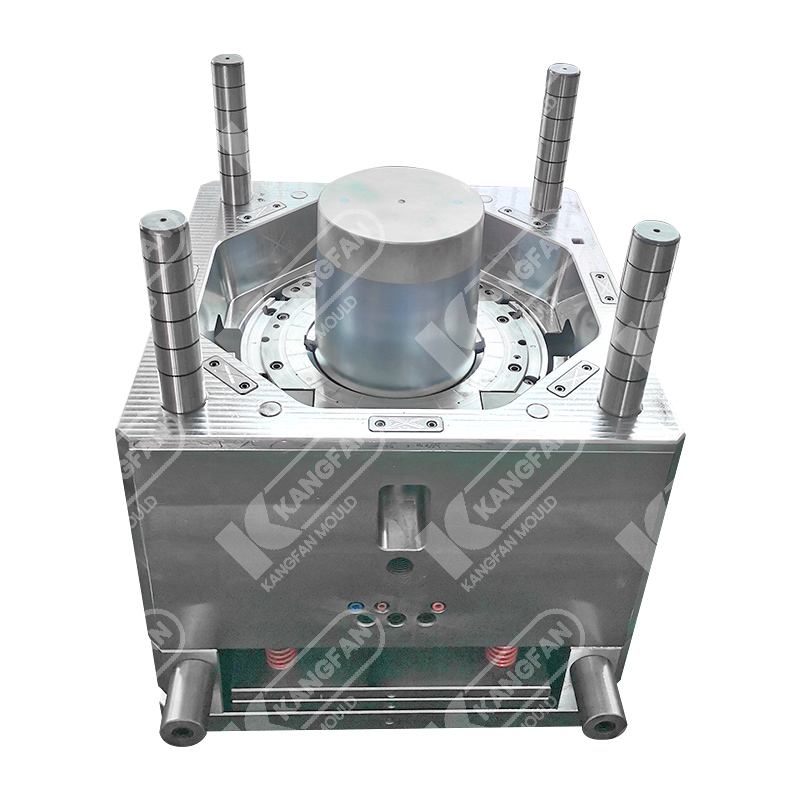

The design of the molds used in Machine Plastic Injection is a critical aspect that influences the final product's success. Mold makers must consider factors such as material flow, cooling channels, venting, and part ejection. Advanced software is often utilized to simulate the injection molding process, allowing designers to improve mold design before actual production begins. This meticulous approach ensures that each part meets stringent specifications and performance requirements.

Machine Plastic Injection also offers remarkable versatility in terms of the types of plastics that can be used. From commodity thermoplastics like polypropylene and polyethylene to engineering resins like ABS and polycarbonate, the process can accommodate a wide range of materials. This adaptability enables manufacturers to select the most suitable plastic based on the desired properties of the end product, such as strength, flexibility, heat resistance, or transparency.

Despite its many benefits, Machine Plastic Injection does present some challenges. For instance, the process requires significant initial investment in both machinery and tooling. Moreover, achieving the good balance between injection pressure, temperature, and mold design can be complex, requiring skilled operators and engineers. However, these challenges are often outweighed by the long-term efficiency and cost-effectiveness that Machine Plastic Injection provides.

In recent years, advancements in Machine Plastic Injection technology have focused on enhancing automation, precision, and sustainability. Automated systems can now handle everything from loading materials to removing finished parts, reducing the need for manual labor and reducing errors. Furthermore, developments in control systems have enabled finer adjustments in the injection process, leading to parts with greater accuracy and less material waste.

Sustainability in Machine Plastic Injection is also becoming increasingly important. Efforts are being made to recycle plastic scraps generated during the process and utilize more environmentally friendly materials. As global concerns about plastic pollution continue to rise, the industry is adapting to incorporate greener practices without compromising on the efficiency that Machine Plastic Injection is known for.

Machine Plastic Injection stands as a testament to the ingenuity of modern manufacturing techniques. Its ability to combine speed, precision, and adaptability has cemented its place as a cornerstone process in the creation of plastic components. As technology continues to advance, so too will the capabilities of Machine Plastic Injection, ensuring that it remains at the forefront of industrial production for years to come.

PREV:The Interplay Of Industrial Molds In Modern ManufacturingNEXT:The Revolution Of Paint Bucket Mould

中文简体

中文简体 English

English

.jpg)